Creating a custom dog toy seems simple, but mistakes can be costly. A bad design is unsafe and a waste of money. Here’s how to avoid those common pitfalls.

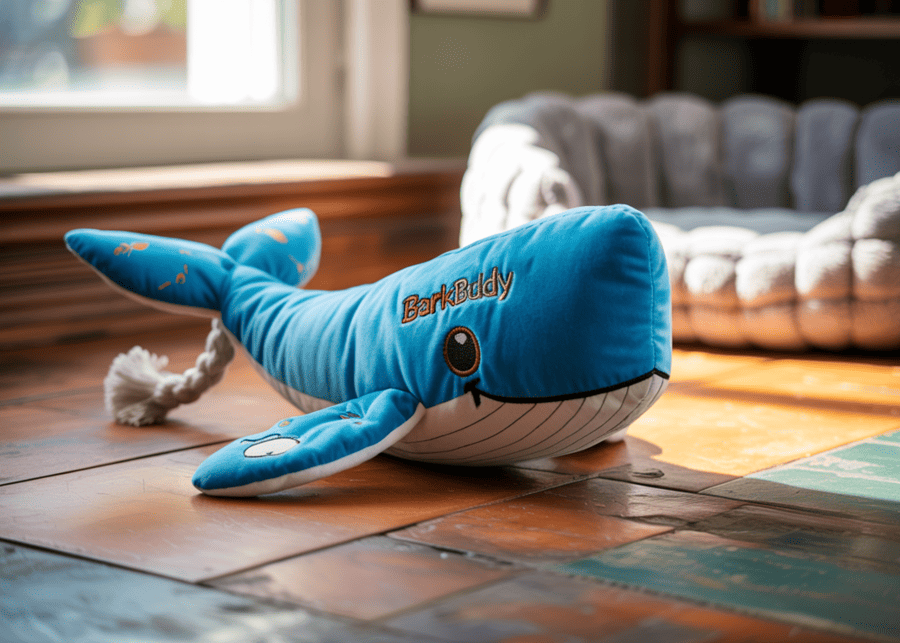

Designing a successful custom plush dog toy involves choosing safe materials, using strong stitching, and selecting colors dogs can see, like blue and yellow. The design must match the dog’s size and play style for maximum safety and enjoyment. This ensures a durable, engaging, and safe product.

I’ve spent over a decade helping brands bring their ideas to life. In my experience, from a simple sketch to mass production, there are many details to consider. As a manufacturer, I’ve seen what works and what doesn’t. Getting these details right is the difference between a best-seller and a forgotten product. Let’s break down everything you need to know, step by step, to create a toy that dogs and their owners will love.

Why do dogs like stuffed toys?

Have you ever wondered why a dog gets so attached to a specific plush toy? Their instincts are powerful. I’ll explain the deep-rooted reasons behind this common behavior.

Dogs love stuffed toys because they appeal to their natural prey instincts. The soft texture mimics the feel of prey, and squeakers inside sound like a small, captured animal. This makes carrying, shaking, and "killing" the toy incredibly satisfying for them.

Dive Deeper: The Psychology Behind the Play

When we design toys, we’re not just making a product; we’re tapping into a dog’s core nature. I’ve learned that understanding these behaviors is crucial for creating a toy a dog will actually choose to play with.

The Call of the Wild: Prey Drive

At their core, dogs are predators. A plush toy allows them to act on these instincts in a safe way. The act of grabbing a toy, shaking it wildly, and hearing it squeak is a simulation of a hunt. The squeaker, in particular, mimics the sound of distressed prey, which triggers a powerful, rewarding response in a dog’s brain. When we designed a pickleball paddle toy for our client Garrett, we made sure it was light enough for dogs to shake, satisfying this very instinct.

Comfort and Companionship

Plush toys aren’t just for destruction. For many dogs, especially puppies, a soft toy can act as a companion. It can replace the comfort they got from snuggling with their mother and littermates. Dogs are social animals, and they can form strong bonds with their toys, often carrying them to bed or greeting you at the door with them. This is why material softness is just as important as durability.

A Tool for Teething

For puppies, chewing is a natural and necessary behavior to relieve the pain of new teeth coming in. A soft plush toy provides a gentle surface for them to bite on, which soothes their sore gums. It’s a much better alternative than your furniture or shoes.

What color toys are best for dogs?

You might love that vibrant red toy, but does your dog even see it properly? A dog’s vision is very different from ours. Choosing the wrong color can make a toy almost invisible to them.

Dogs see a limited color spectrum, similar to red-green color blindness in humans. The best colors for dog toys are blue and yellow, as they stand out clearly against most backgrounds, like green grass. Avoid red, orange, and green.

Dive Deeper: Seeing Through a Dog’s Eyes

For years, people believed dogs saw in black and white. Scientific research has shown this is not true, but their world is definitely less colorful than ours. This knowledge is critical when we design a toy meant to be found and fetched.

Understanding Canine Vision

Humans have three types of color-detecting cone cells in their eyes, allowing us to see a full spectrum (trichromatic vision). Dogs only have two types of cone cells (dichromatic vision). They see the world primarily in shades of blue, yellow, and gray. Colors like red, orange, and green likely appear as shades of brownish-gray or yellow.

The Science of Dog-Friendly Colors

A 2013 study published in the Proceedings of the Royal Society B confirmed that dogs can distinguish colors. They consistently chose objects of a specific color over others, proving they use color as a cue. Based on how their eyes work, blue and yellow are the most distinct and vibrant colors to them.

Practical Color Choices for Toy Design

When a client asks for a new toy design, I always bring up color. A red ball thrown on a green lawn can be very difficult for a dog to locate. A blue ball, however, provides a sharp contrast. This is why we guide our clients toward a dog-friendly palette.

| Color | How Humans See It | How Dogs Likely See It | Toy Visibility |

|---|---|---|---|

| Blue | Bright Blue | Bright Blue | Excellent |

| Yellow | Bright Yellow | Bright Yellow | Excellent |

| Red | Bright Red | Brownish / Dark Gray | Poor |

| Green | Bright Green | Yellowish-Gray | Poor |

| Orange | Bright Orange | Brownish-Yellow | Poor |

What Materials Are Safe for Dog Plush Toys and Which Should You Avoid?

The material of a toy can mean the difference between safe play and an emergency vet visit. Many common fabrics are actually dangerous. I’ll show you what to choose and what to avoid.

Safe materials for dog plush toys include durable fabrics like Cordura, ballistic nylon, and reinforced, multi-layered plush. Always use non-toxic dyes. Avoid materials with small, detachable parts like plastic eyes or beads, and fabrics that shred easily, which can be choking hazards.

Dive Deeper: The Foundation of a Safe Toy

As a manufacturer, raw material control is the first and most critical step in our quality assurance process. A great design is worthless if the material is unsafe or falls apart. I always tell my clients that the fabric choice is non-negotiable for safety.

Safe Fabric Checklist

The goal is to find materials that can withstand chewing, pulling, and washing without breaking down into ingestible pieces.

- Ballistic Nylon/Cordura: These are my top choices for durable toys. They were originally designed for military applications, so they have excellent resistance to tears and abrasion.

- Reinforced Plush: For clients who want that classic soft feel, we use plush fabric with a second, tougher layer fused underneath. This provides softness on the outside and strength on the inside.

- Denim or Canvas: Heavy-duty, tightly woven cotton fabrics can be a good choice. They are strong but can fray over time, so seam quality is crucial.

Hidden Dangers to Avoid

I’ve seen many toys from other factories with dangerous components. These are things we absolutely refuse to use.

- Small Plastic Parts: Plastic eyes, noses, or buttons are a major choking hazard. They can be chewed off and swallowed. We always use embroidery for these details.

- Shreddable Fabrics: Cheap felt or standard fleece can be torn apart easily. A dog can ingest the shredded pieces, leading to intestinal blockage.

- Toxic Dyes: We ensure every batch of fabric is tested for harmful chemicals. A dog will have this toy in its mouth, so non-toxic materials are essential.

| Safe Materials | Why They’re Safe | Unsafe Materials | Why They’re Unsafe |

|---|---|---|---|

| Ballistic Nylon | Tear-resistant, highly durable | Standard Felt | Shreds easily, ingestion risk |

| Reinforced Plush | Double-layered for strength | Hard Plastic Parts | Choking hazard, can break teeth |

| Embroidered Details | Securely stitched, cannot be swallowed | Small Beads/Buttons | Easily chewed off, choking hazard |

| Non-Toxic Dyes | Prevents poisoning from licking/chewing | Lead-Based Dyes | Highly toxic if ingested |

How Do Dog Size and Breed Affect Custom Plush Toy Design Requirements?

A toy that’s perfect for a Chihuahua could be a deadly choking hazard for a German Shepherd. Size and breed matter immensely. Designing a "one-size-fits-all" toy is a recipe for disaster.

Toy design must match the dog’s size and jaw strength. Small breeds need smaller, lighter toys they can carry. Large breeds with strong jaws, like Pitbulls, require larger toys made from highly durable materials with reinforced stitching to prevent destruction and ingestion.

Dive Deeper: Engineering for the Individual Dog

When a client like Judy from Germany, who owns a pet store chain, sends us a sourcing list, we don’t just pull items off a shelf. We discuss the target audience for each toy. Is it for small city dogs or large country dogs? This changes everything.

Designing for Small Breeds (e.g., Yorkie, Pomeranian)

For small dogs, the toy needs to be lightweight and easy for their little mouths to grip and carry. A heavy, oversized toy won’t be fun for them. We focus on softer plush materials and smaller squeakers that are easy to activate. The risk here is less about destruction and more about making the toy engaging and manageable.

Meeting the Needs of Medium Breeds (e.g., Beagle, Cocker Spaniel)

This group is versatile. They enjoy a mix of play styles, from fetching to light tugging. Designs for them can be more varied, but durability starts to become a more significant factor. We often recommend reinforced plush and double-stitched seams for this category.

Engineering for Large and Powerful Breeds (e.g., Labrador, German Shepherd, Pitbull)

This is where our engineering is truly tested. For large breeds and known power chewers, durability is the top priority.

- Size: The toy must be large enough that it cannot be swallowed whole.

- Material: We use materials like ballistic nylon or multi-layered, reinforced fabrics.

- Construction: Seams are double- or even triple-stitched with heavy-duty thread. We often add a binding over the seams as an extra layer of protection.

| Dog Size | Key Design Considerations | Example Materials |

|---|---|---|

| Small | Lightweight, easy to carry, small squeakers | Standard Plush, Soft Canvas |

| Medium | Versatile shapes, moderate durability | Reinforced Plush, Denim |

| Large/Power Chewer | Extreme durability, reinforced seams, large size | Ballistic Nylon, Cordura |

What Are the Essential Safety Standards for Custom Dog Plush Toys?

You believe your toy is safe, but does it meet established safety standards? Selling an unsafe toy can harm dogs and lead to legal trouble. I’ll explain the key certifications you can’t afford to ignore.

While no mandatory global standard exists specifically for pet toys, we at Preeminent adhere to the strict standards for children’s toys, such as ASTM F963 in the USA and EN 71 in Europe. These cover chemical safety (no lead), physical safety (no sharp points), and flammability.

Dive Deeper: Our Commitment to Safety and Quality

Safety isn’t just a buzzword for us; it’s a core part of our manufacturing process. Because there isn’t a government-enforced law for pet toy safety in most countries, we take the initiative to hold ourselves to a higher standard. I always tell my clients, "If it’s not safe enough for a child, it’s not safe enough for a pet."

Borrowing from Children’s Toy Standards

Children’s toy standards are incredibly rigorous because children, like pets, can chew on and ingest parts of toys.

- ASTM F963 (USA): This is the "Standard Consumer Safety Specification for Toy Safety." It sets requirements for physical and mechanical properties. It ensures there are no sharp edges or points, and that small parts don’t detach and become choking hazards.

- EN 71 (Europe): This is the European equivalent. It is especially strict on chemical safety, testing for a wide range of toxic substances like lead, mercury, and phthalates.

Key Chemical and Physical Tests

When we produce a toy, the materials and final product undergo testing to meet these standards. This includes:

- Chemical Analysis: We test fabrics and dyes to ensure they are free from heavy metals and other harmful substances.

- Tension Tests: We pull on seams, tails, and ears to ensure they don’t detach easily under force.

- Bite Tests: We simulate the force of a dog’s jaw to check for material integrity.

- Choke Hazard Assessment: We check every component against small parts cylinders to ensure they are not a choking risk.

Our commitment to these standards is part of our quality guarantee. It’s how we build trust with our clients and ensure the end-user—the dog—is safe.

How to Choose the Right Filling Materials for Durable Dog Plush Toys?

The inside of a toy is just as important as the outside. The wrong filling can clump together, lose its shape, or even be toxic if ingested. I’ll reveal the best options for long-lasting fun.

For durable dog plush toys, the best filling is high-quality, resilient polyester fiberfill (polyfill) that is non-toxic and hypoallergenic. It holds its shape after chewing and washing. Avoid fillings like cotton, foam, or beans, which can be choking hazards if ingested.

Dive Deeper: What’s on the Inside Counts

I’ve seen many toys get returned not because the outer fabric failed, but because the filling became a lumpy, useless mess after one wash. Or worse, the dog tore the toy open and the filling posed a health risk. Choosing the right stuffing is a critical design decision.

The Gold Standard: Polyester Fiberfill

There’s a reason we almost exclusively use 100% new polyester fiberfill.

- Resilience: It bounces back and doesn’t clump easily, so the toy keeps its shape even after rough play.

- Non-Toxic & Hypoallergenic: This is crucial since dogs will have the toy in their mouths. We ensure our polyfill is clean and safe.

- Moisture Resistant: Unlike natural fibers, it doesn’t absorb water, which prevents mold and mildew from growing inside the toy. This also means it dries quickly after being washed.

- Machine Washable: It holds up well in the washing machine, which is a huge selling point for pet owners.

Fillings You Must Avoid

When clients come to us after a bad experience with another factory, it’s often because a cheaper, unsafe filling was used.

- Cotton or Natural Fibers: These absorb moisture, clump easily, and can become a breeding ground for bacteria.

- Foam Scraps: Scraps of foam can be easily ingested and can cause choking or intestinal blockages.

- Beans, Pellets, or Nutshells: These are major choking hazards. If the toy rips open, a dog could ingest hundreds of tiny parts.

We ensure that every toy we make, whether it’s an ODM project or a one-stop sourcing item, uses only the safest, highest-quality filling.

What Stitching Techniques Prevent Dogs from Destroying Plush Toys Quickly?

Is your dog a "super chewer" that destroys toys in minutes? The secret to durability isn’t just the fabric; it’s the stitching. I’ll show you the manufacturing techniques we use to build stronger toys.

To make plush toys durable, use reinforced stitching techniques. This includes double-stitching all seams, using strong nylon or polyester thread, and adding a protective binding or welt over the seams. This prevents dogs from easily tearing the toy apart at its weakest points.

Dive Deeper: Building a Fortress, Not Just a Toy

A dog’s first instinct when trying to destroy a toy is to find a weak point, and that is almost always the seam. I’ve learned from years of manufacturing that a toy is only as strong as its stitches. This is where craftsmanship really makes a difference.

The Power of Reinforced Seams

A single line of stitching is simply not enough for a dog toy. Here are the methods we rely on:

- Double Stitching: Every seam is stitched twice. This provides a backup if one line of stitching is compromised.

- Inverted Seams with Topstitching: We sew the seam on the inside, then turn the toy right-side-out and add another line of stitching on the outside. This creates a very strong, flat seam that’s harder for a dog’s teeth to grab.

- Adding a Welt or Binding: For toys designed for extra-tough chewers, we fold a piece of durable fabric, like canvas or nylon webbing, over the seam and stitch it down. This acts like armor, protecting the stitches from direct attack.

Choosing the Right Thread

The type of thread used is just as important as the stitching technique. We never use standard cotton thread, as it’s weak and absorbs moisture. We exclusively use heavy-duty polyester or nylon thread, which is resistant to rot and has a much higher tensile strength.

Strategic Seam Placement

Good design also involves thinking about where the seams are placed. Whenever possible, we design toys to have fewer seams overall. We also try to place them in locations that are less likely to be targeted by a dog’s chewing, like along flat surfaces rather than on protruding edges. This combination of strong techniques and smart design is how we create toys that last.

How to Design Plush Toy Shapes That Match Dogs’ Natural Play Behaviors?

A toy that looks cool to you might be boring for a dog. The best designs tap into their natural instincts for play. I’ll explain how to create shapes that dogs simply can’t resist.

Design shapes that support natural behaviors like shaking, fetching, and tugging. Long, skinny shapes are great for shaking. Round or disc shapes are good for fetching. Toys with multiple appendages or knotted ropes are perfect for tug-of-war.

Dive Deeper: Designing for Instinct

When I work with a brand owner on a new custom toy, my first question is always, "What do you want the dog to do with this toy?" The shape is the primary driver of the play style. A well-designed shape makes the toy intuitive and more engaging for the dog.

Designing for Different Play Styles

We can categorize most play behaviors and design shapes that specifically encourage them. This is how we ensure the toy is not only fun but also functional.

| Play Behavior | Ideal Toy Shape | Key Design Features |

|---|---|---|

| Shaking | Long, skinny, floppy (e.g., snake, octopus) | Easy to grip in the middle, satisfying floppy ends. This mimics shaking prey. |

| Fetching | Ball, disc, stick | Aerodynamic for throwing, easy for a dog to pick up and carry back. |

| Tugging | Ropes, rings, toys with handles or multiple parts | Provides durable, comfortable grip points for both the dog and the owner. |

| Cuddling | Soft, rounded, pillow-like | Made with softer plush, often with a gentle or no squeaker, for comfort. |

| Problem-Solving | Puzzle toys with hidden compartments | Encourages mental stimulation as the dog works to find a hidden treat. |

When we worked with Garrett on his pickleball paddle toy, it was a brilliant example of form meeting function. The paddle shape was instantly recognizable for his brand, but it also served as a great "stick" shape for fetching and a good "floppy" shape for carrying and shaking. The design successfully merged his brand identity with a dog’s natural play behaviors.

How Long Does the Custom Dog Plush Toy Design and Production Process Take?

You have a great idea for a custom toy, but how long will it be until it’s in your warehouse? The timeline can be longer than you think. I’ll give you a realistic breakdown of the entire process.

The entire custom dog plush toy process, from initial design to mass production and shipping, typically takes 90 to 120 days. This includes design finalization (1-2 weeks), prototyping (2-3 weeks), mass production (30-45 days), and shipping (30-60 days).

Dive Deeper: From Concept to Container

I believe in being transparent with my clients about timelines. Understanding each phase helps manage expectations and ensures a smooth process. Delays can happen, but a clear roadmap helps us stay on track. Here is the typical journey of a custom toy at our company.

Phase 1: Design and Prototyping (Approx. 3-4 Weeks)

This is where the idea takes physical form.

- Concept & Design (7-10 days): You provide us with your idea, sketch, or requirements. Our design team creates a professional technical drawing, specifying materials, colors, and construction.

- Prototyping (15-20 days): We create the first physical sample. We then ship this prototype to you for approval. This phase can involve one or two rounds of revisions to get everything perfect. Clear communication here is key to avoiding delays.

Phase 2: Mass Production (Approx. 30-45 Days)

Once you approve the final prototype, we move to full production.

- Material Sourcing & Cutting: We order and inspect all raw materials.

- Cutting, Stitching, & Assembly: The fabric is cut, details are embroidered, and the toys are sewn together.

- Stuffing & Finishing: The toys are filled, the final seams are closed, and they go through an initial quality check.

Phase 3: Quality Control and Shipping (Approx. 35-65 Days)

- Final QC (5 days): Our dedicated quality team inspects the finished products, verifying them against the approved prototype and your order specifications. We check for quality, quantity, and packaging.

- Shipping (30-60 days): This is the longest and most variable part of the timeline. Sea freight is the most common and cost-effective method, but it takes time. We provide photos of the packed goods and container loading for your verification before it leaves our hands.

Our 24/7 one-on-one support is crucial during this entire process to keep you informed and keep the project moving forward.

How to Test Custom Plush Toy Prototypes with Real Dogs Before Mass Production?

Your prototype looks perfect, but will dogs actually play with it? And more importantly, will it hold up? Skipping real-world testing with actual dogs is a huge risk I always advise against.

Test prototypes with a diverse group of dogs representing different sizes, breeds, and chew strengths. Observe their initial interest, how they play with it, and identify any weak points. Collect feedback from owners on durability and engagement before approving mass production.

Dive Deeper: The Ultimate Quality Control

A lab test can tell you a material’s tensile strength, but it can’t tell you if a dog finds a toy fun. Before a client signs off on a mass production run, I strongly encourage them to conduct field testing. This is the final and most important check to ensure the product will be a success in the market.

Assembling Your Canine Test Panel

A good test requires a variety of testers. You wouldn’t test a car on just one type of road.

- Size Diversity: Include small, medium, and large dogs.

- Chew Style Diversity: You need at least one gentle chewer, a moderate player, and a "power chewer" who lives to destroy toys. This will quickly reveal the toy’s absolute limits.

- Breed Diversity: Different breeds have different play styles. A retriever might love to fetch it, while a terrier might prefer to shake it.

What to Look For During Testing

Give the prototype to the dogs and watch closely.

- Initial Interest: Does the dog immediately engage with the toy, or ignore it?

- Play Style: How does the dog play with it? Shaking, fetching, chewing, cuddling? Does the shape facilitate this play?

- Weak Points: Which part of the toy does the dog attack first? Is it the ears, the tail, a seam? This is invaluable information for reinforcing the design.

- Durability: How long does it take for the toy to show signs of damage? Does it last five minutes or five days?

Gathering and Applying Feedback

Ask the dog owners to provide simple feedback. Did your dog like it? Did any pieces come off? Based on this real-world data, we can make final adjustments—like reinforcing a commonly attacked seam or changing a material—before committing to thousands of units. This step saves money and prevents negative reviews down the line.

What Common Design Mistakes Lead to Failed Custom Dog Plush Toys?

Many custom toys fail before they even launch. From my experience as a manufacturer, these failures are often due to a few common, easily avoidable mistakes. I’ll share the biggest pitfalls I’ve seen.

Common mistakes include using unsafe or cheap materials, weak stitching, and designing for human aesthetics over dog-friendly function. Other critical failures are creating "one-size-fits-all" toys that are unsafe for some dogs, and adding small, decorative parts like plastic eyes that become choking hazards.

Dive Deeper: Learning from Common Failures

Clients often come to us after having a bad experience with another supplier. The stories are usually the same and boil down to a few key errors. Understanding these helps new brand owners avoid them from the start.

Mistake 1: The "Too Pretty to Play" Problem

This happens when a designer prioritizes looks over durability. They create a beautiful, intricate toy with delicate parts, thin fabrics, and decorative elements. It looks fantastic on a store shelf but gets destroyed in seconds.

- Our Solution: We always start the design conversation with durability. We use techniques like embroidery for details instead of appliqué and choose fabrics that can withstand play. Aesthetics are important, but for a dog toy, function must come first.

Mistake 2: Ignoring the Chew Factor

This is the most common reason for toy failure. The client or previous manufacturer underestimates the power of a dog’s jaw. They use single stitching, weak thread, or fabric that isn’t tear-resistant.

- Our Solution: We design for the "worst-case chewer." By using reinforced seams, durable materials like ballistic nylon, and strong thread, we build toys that are prepared for rough play.

Mistake 3: Forgetting the End User (The Dog)

Designers sometimes create toys that appeal to human sensibilities. They use colors dogs can’t see well (like red), shapes that are awkward for a dog to carry, or sounds that aren’t engaging.

- Our Solution: We design through the eyes and instincts of a dog. We use a dog-friendly color palette (blues and yellows), create shapes that align with natural play behaviors, and use squeakers that trigger their prey drive. A successful toy is one the dog chooses, not just the one the human buys.

How to Balance Aesthetic Appeal with Functional Durability in Dog Toy Design?

You want a toy that looks great on the shelf and also survives a vigorous play session. It can feel like an impossible balance to strike. But with the right approach and manufacturing partner, you can have both.

Balance aesthetics and durability by using durable, printable fabrics for the main body of the toy. Use high-quality embroidery for logos and facial details instead of unsafe plastic parts. Design clever shapes that are both visually appealing and structurally sound, with reinforced seams in high-stress areas.

Dive Deeper: The Art of Smart Design

This is the ultimate challenge and where true expertise comes in. At Preeminent, this is what we do every day. We help brands create products that are both marketable and long-lasting. It’s not about compromise; it’s about making smart choices.

Smart Material and Construction Choices

You don’t have to use drab, industrial-looking materials to make a toy tough.

- Printable Durability: We can use dye-sublimation printing on tough polyester canvas or similar fabrics. This allows for vibrant, full-color custom designs and branding on a material that is also highly durable.

- Mixed Media: We can construct a toy using a super-tough material like Cordura for the main body and add accents of softer, colorful plush in areas that are less likely to be chewed. This gives the toy visual and textural appeal without sacrificing its core strength.

Embroidery Over Appliqué

A common way to add detail is to sew on separate pieces of fabric (appliqué) or use plastic parts. Both are weak points.

- The Power of Embroidery: We use high-density embroidery to create logos, eyes, and other details directly onto the fabric. It’s incredibly durable, completely safe, and gives the toy a premium, high-quality look. It’s a perfect fusion of aesthetics and safety.

Structural Integrity in Design

The shape itself can be both beautiful and strong.

- Minimize Weak Points: We design shapes that flow and have fewer sharp, protruding parts that invite chewing. For example, instead of long, thin, easily detached legs on an animal toy, we might design shorter, thicker legs that are integrated into the body.

The pickleball paddle toy we made for Garrett is a prime example. The shape was unique and directly tied to his brand’s aesthetic. At the same time, its simple, solid form with no easy-to-rip-off parts made it inherently durable. This is the balance we strive for.

Conclusion

Designing a great custom dog toy requires careful thought about safety, durability, and a dog’s natural needs. Partner with Pre-emiennt to bring your vision to life successfully.