Wholesale and Custom

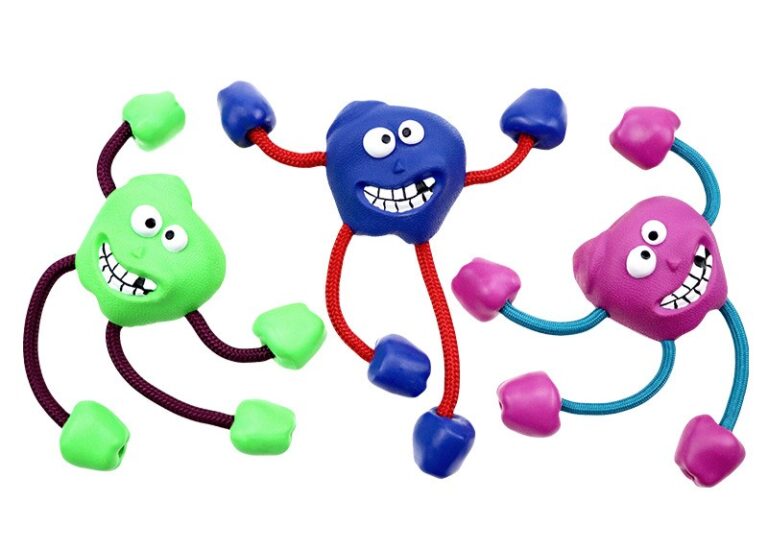

Rubber TPR Nylon Silicone

Dog Chew Toys Manufacturer

We provide one-stop solutions for your private label OEM/ODM dog chew toys production, making it easy to build your own brand.

Your Brand, Your Dog Chew Toys, Expertly Made

Pre-eminet is a leading rubber dog toy manufacturer that our dog toy factory also uses TPR, nylon, and silicone materials for different chewing needs. We provide wholesale, OEM, and complete customization services, so you can turn your brand into the kind of toys that dogs get excited about and pet parents feel good buying.

Teething Chew Rubber Toys

"Premium rubber teething toys with calibrated durability - delivering developmental support and elevating your brand's professional value."

Squeaky Rubber Dog Toys

"Advanced squeaker technology integrated with reinforced rubber design play engagement while ensuring lasting durability for your premium line."

Treat Dispenser Rubber Toys

"Advanced treat-dispensing mechanism with optimized rubber density - driving sustainable engagement and positioning your brand"

Interactive Rubber Dog Toys

"Precision-engineered interactive rubber toys with multi-point stimulation - elevating your product line into the high-performance engagement category."

TPR Dog Toys

"Medical-grade TPR formulation with enhanced molecular stability - delivering superior flexibility and durability for your premium safety-focused portfolio."

Nylon Dog Toys

"Industrial-grade nylon construction with reinforced molecular bonds - delivering exceptional tensile strength for your professional-grade durability segment."

Silicone Dog Toys

"Food-grade silicone with optimized thermal resistance - ensuring superior safety standards and longevity for your premium non-toxic collection."

TPR Cooling Dog Toys

"TPR material with sustained cooling properties - differentiating your summer collection with scientifically-proven comfort features."

Private Label our ready-to-ship designs

Over 10,000 available designs ready for your branding. Quick turnaround and minimal setup costs.

Go Fully Custom (ODM)

Unique molds, fabrics, and innovative features developed just for you. Bring your vision to life with our expertise.

One-on-One Partnership

We partner with you one-on-one to bring your vision to life. Explore our flexible manufacturing levels below.

Ideas + Manufacturing = Success

Your Custom pet supplies Ideas + Our Expert Manufacturing = Market Success. We turn concepts into profitable products.

Dedicated OEM/ODM Support

We specialize in bringing brand owners' unique pet supplies concepts to life with consistent quality and dedicated end-to-end support.

Boost Your Margins

Get Factory-Direct Pricing. Cut out middlemen and maximize your profit potential with our competitive manufacturing rates.

Hey there! Have some innovative ideas been popping into your head?

Why not bring them to the table? Let's chat and explore the possibilities together. Our team of experts is ready to transform your dog toys concepts into reality.

All You Need To Know About Dog Chew Toys

Dog chew toys are specially designed interactive products that provide mental stimulation, dental health benefits, and anxiety relief for dogs. These toys use safe materials like natural rubber, nylon, TPR and other tough materials that can handle lots of chewing without breaking apart. They give dogs something appropriate to chew on instead of furniture or shoes.

Consider a chew toy when there is imminent damage due to destructive behavior or to prevent boredom and anxiety. Select the appropriate size and material based on the dog's chewing habits to ensure safe and effective use.

This article discusses popular topics on dog chew toys, including their applications, mechanisms, buying considerations, as well as the different classifications of chew toys suitable for various dog breeds and ages.

What Are Dog Chew Toys Used For?

Since dog chew toys serve multiple purposes, common applications are tied to behavioral and health issues.

Alone time activities where destructive chewing is an issue

Training aids where positive reinforcement helps with behavior modification

Daily entertainment that keeps dogs mentally stimulated

Dental health applications that need plaque removal

Anxiety relief applications that reduce stress and nervous behavior

Teething relief for puppies experiencing discomfort

How Do Dog Chew Toys Work?

A chew toy's primary function is to serve as a safe and effective proxy for objects a dog is naturally driven to chew. It works by channeling the innate masticatory drive—an instinct for gnawing and tearing—away from destructive behaviors and onto an object engineered specifically for this purpose. Its fundamental job is to provide a safe, designated outlet for this powerful biological need.

Mechanically, a chew toy works by providing sustained resistance to the compressive and torsional forces of a dog's jaw. A well-engineered toy is designed to yield satisfyingly under pressure without catastrophic failure. Unlike household items, its material composition is formulated for safe wear, breaking down through gradual abrasion or granulation rather than fracturing into sharp, hazardous shards. This controlled degradation is a key working principle.

Beyond simple resistance, a chew toy works by creating a self-reinforcing feedback loop. The design is intended to progressively reward the dog's effort, which sustains engagement over time. Whether the "reward" is the release of an embedded flavor, the satisfying tactile sensation from surface textures, or the eventual dispensing of a treat, the toy is an active participant. This mechanism transforms simple chewing into a continuously rewarding activity.

Attraction Mechanisms of Chew Toys

A rubber dog chew toy's effectiveness is driven by engineered sensory triggers. Complex surface textures provide critical tactile feedback and promote dental health. Our proprietary flavor-infusion process, embedding scents like beef or milk deep within the polymer, ensures a long-lasting scent profile. Additionally, puzzle mechanics transform play into a rewarding, problem-solving activity for cognitive enrichment.

Difference from Traditional Toys

Unlike plush or interactive items, chew toys are engineered for one purpose: to withstand intense, prolonged mastication. Their material is designed for safe, gradual wear—not the catastrophic failure (tearing, splintering) seen in toys not intended for this specific, high-stress function. This difference in designed purpose and failure mode is fundamental.

Material science is the core of how a chew toy works. We select specific polymers (e.g., Rubber, TPE, Nylon) for their precise balance of durability and elasticity to absorb bite force without fracturing. Critically, our commitment to using natural, non-toxic materials ensures that even as the dog chew toy wears down, it remains safe for dogs.

Why Choose Dog Chew Toys?

Promotes Oral Health

Natural chewing action helps remove plaque and tartar buildup, keeping teeth clean and gums healthy for better dental hygiene.

Relieves Separation Anxiety

Provides mental stimulation and comfort during alone time, reducing destructive behaviors and stress-related issues.

Intellectual Development Training

Interactive features challenge problem-solving skills and cognitive abilities, promoting mental development and learning.

Long-term Economic Benefits

Durable construction ensures extended use, providing excellent value while reducing replacement costs over time.

Considerations When Wholesale and Customizing Dog Chew Toys

The ideal dog chew toy is the one that perfectly matches your target market's needs and can provide safe, engaging entertainment for dogs. However, most wholesale buyers choose chew toys based on price alone rather than considering the full range of factors that determine success in the market.

Many fail to understand the importance of material performance since it directly impacts customer satisfaction and repeat purchases. The material used for the toy construction is a priority factor that affects durability, safety, and overall user experience. If there isn't enough consideration given to material selection, the product tends to fail in the market and damage brand reputation.

#1 Material Compatibility

Material selection has a great impact on product positioning and market success. The material should be compatible with the intended use case, target dog size, and safety requirements. Different materials offer varying levels of durability and appeal to different market segments.

Rubber Material

Natural safety + excellent elasticity + suitable for daily chewing activities with moderate intensity.

TPR Material

Soft comfort + easy to clean + suitable for puppies and gentle chewers with sensitive teeth.

Nylon Material

Ultra-durable + suitable for heavy chewing + long-lasting use for aggressive chewers.

Silicone Material

Food-grade safety + easy to sterilize + suitable for sensitive dogs with allergies.

#2 Market Positioning

The market positioning determines the target audience and price point for your chew toys. Consider breed-specific preferences, size requirements, and customer demographics when planning your product line.

#3 Bite Strength Assessment

Factors such as dog size, breed characteristics, individual chewing habits, and age affect the required durability levels and safety considerations for optimal product performance.

#4 Functional Requirements

The right functional features determine customer satisfaction and market appeal. Consider dental cleaning benefits, treat dispensing capabilities, interactive elements, and entertainment value when designing your product specifications.

#5 Usage Scenario Analysis

Different usage scenarios require different design approaches. Indoor toys, outdoor toys, travel companions, training aids, and solo entertainment options each have unique requirements for materials, size, and functionality.

#6 Quality Standards & Certification

Quality standards determine market acceptance and legal compliance. Consider pet safety certifications, material testing requirements, and international quality standards when selecting manufacturing partners and product specifications.

Dog Chew Toys Product Classification Guide

Dog Chew Toys Types By Material

Dog chew toys come in different materials. Each of these materials brings different advantages and benefits. The different materials allow suitable applications for various dog breeds, sizes, and chewing intensities.

Rubber Series

Natural rubber material offers excellent elasticity + high bite resistance + eco-friendly composition. This material is best suited for moderate to heavy chewers who need durable yet safe options.

TPR Series

Thermoplastic rubber provides soft safety + colorful options + easy cleaning properties. This material works well for puppies and gentle chewers who prefer softer textures.

Nylon Series

Super durable nylon construction provides long-lasting companionship + economic practicality for heavy chewers. This material can withstand aggressive chewing while maintaining structural integrity.

Silicone Series

Food-grade silicone ensures safety + gentle material properties + suitability for all dogs. This material is particularly beneficial for sensitive dogs or those with food allergies, providing a non-toxic and hypoallergenic option.

Dog Chew Toys Types By Function

Squeaky chew Toys

Rubber or TPR squeaky chew toys combine durable chewing surfaces with engaging sound elements. These toys feature built-in squeakers that activate when dogs bite or chew, creating auditory stimulation that enhances the chewing experience. The squeaky sound triggers natural prey drive instincts + maintains interest during extended chew sessions + provides rewarding feedback for appropriate chewing behavior. The rubber/TPR construction offers long-lasting durability while being gentle on teeth and gums.

Treat-Dispensing Toys

Treat-dispensing chew toys feature hollow chambers or textured grooves that hold food rewards, releasing them as dogs chew and play. These toys extend chewing sessions + provide mental stimulation + slow treat consumption for better digestion. The dispensing action rewards natural chewing behavior while keeping dogs engaged for longer periods. Different treat sizes and filling techniques can adjust the difficulty level to match your dog's chewing style and skill level.

Dental Chew Toys

Dental chew toys are specifically designed with textured surfaces and firm materials for oral health benefits. These toys clean teeth + strengthen gums + relieve teething discomfort through natural chewing action. The mechanical action helps remove plaque buildup and promotes healthy dental hygiene habits.

Interactive Toys

Interactive chew toys are designed for fetch, tug-of-war, and retrieval games between dogs and owners. This category includes rubber balls for throwing, frisbees for outdoor play, rope-integrated tug toys, and floating fetch toys for water activities. These toys promote physical exercise + strengthen human-dog bonds + provide outlet for natural chase and retrieval instincts. The durable construction withstands interactive play while maintaining safe chewing properties when dogs carry or mouth the toys.

Our Advantages and Services

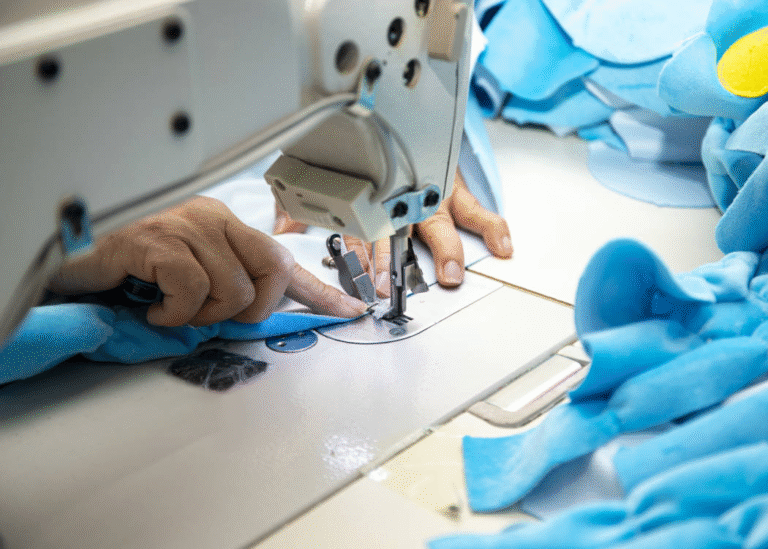

Professional manufacturing capabilities / Self-production and sales / Design capabilities - One-stop service

Our Factory Products

Natural Rubber

Food-grade safety standards / Premium raw materials / Professional testing

SafeIntegrated Production

Complete industry chain from design to finished products / No intermediaries / Reduced communication costs

EfficientOn-time Delivery

Strong sampling and delivery capabilities / Daily production capacity: 300,000 pieces

FastOther Market Products

Inferior Rubber

Prone to deformation and cracking / Short lifespan / Environmental pollution

Processing Only

Lack design capabilities / Require separate design development and mold processing

Low Production Efficiency

Small workshops / Insufficient personnel and equipment / Quality below standards

Providing You with One-on-One Service

Meeting your personalized requirements

Factory has over 10 years of foreign trade experience, exported to 50+ countries

Independent rubber material supply chain, complete production supply reduces costs and improves production technology

Over 13 QC quality inspections, ensuring 100% qualification rate for all products

Support free sampling, annual samples worth containers

Customization Process

On-demand design / Customization saves worry

1. Consultation & Discussion

Requirements communication + Preliminary solution

2. Custom Design

Drawing analysis + Technical assessment

3. 3D Sampling & Quotation

Sample production + Cost calculation

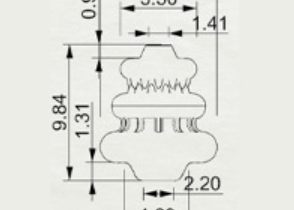

4. Mold Design

3D modeling + Structure optimization

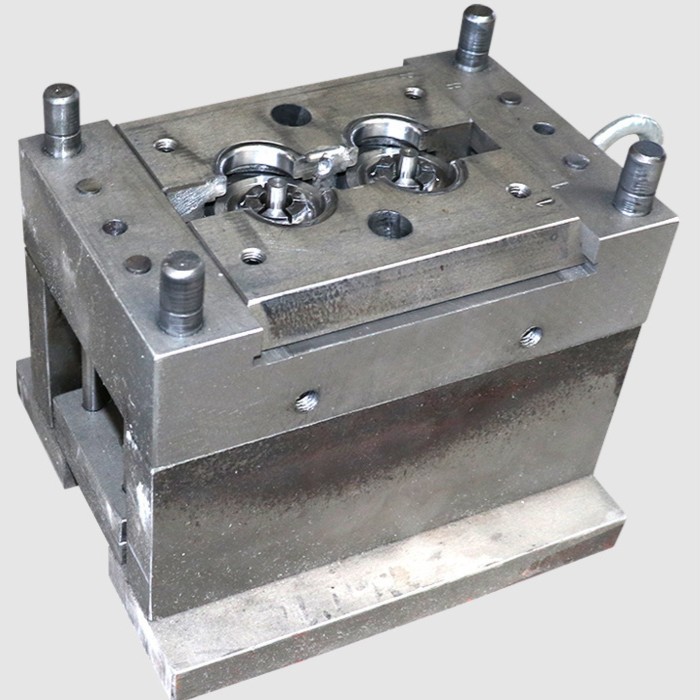

5. Mold Production

Mold manufacturing + Trial production verification

6. Quality Check & Delivery

Quality inspection + Packaging and delivery

Mold Development

Professional product design capabilities / Self-owned workshop supports mold development

Development Process

- Product analysis and design optimization

- Product structure material selection

- Multi-component mold design

- Design feasibility analysis

Rubber Precision Mold Solutions

Mold Types

- Compression molding molds

- Transfer molding molds

- Injection molding molds

- Extrusion molding molds

Manufacturing That Scales With Your Pet Brand: Find Your Perfect Fit

We understand that pet businesses operate at different phases – whether you're a startup, growing, or an established brand. That's why we offer flexible manufacturing paths designed to meet your specific needs:

Level 1: Private Label Our Stock

Fast Launch: Select from our 10,000+ unique, ready-to-manufacture dog chew toy designs.

Your Branding: We add your custom swing tags, boxes, stickers, or backboards. Perfect for speed to market, ideal for startups.

Level 2: Modify Existing Designs

Enhanced Branding: Modify stock items without new molds.

Examples: Laser your logo onto rubber chew toys, print your design directly on the surface, or create custom molds with built-in logos. Great for growing businesses wanting unique touches. Perfect for adding unique touches efficiently.

Level 3: Full Custom Design & Manufacturing (ODM)

Unique Products: Partner with us one-on-one to design and create entirely new, innovative dog chew toys from scratch.

Capabilities: Leverage our full design, 3D modeling, 3D printing, and mold development expertise for market-leading rubber chew toys. Perfect suited for mature brands.

Ready to Learn More? Contact Us to discuss your specific project needs.

Our Manufacturing Facility

Take a virtual tour of our state-of-the-art pet supplies manufacturing facility where quality and innovation come together to create premium products for your brand.

What Our Clients Say

Hear from pet brand owners who've partnered with us for their custom pet products manufacturing needs.

Johnson

PawPerfect, USA

"Preeminent transformed our rough sketches into the most adorable plush toys our customers have ever seen. Their attention to detail and quality control is exceptional. We've been working together for 3 years now, and they've become an essential partner for our brand's growth."

Mark Thompson

BarkBoy, Australia

"When we needed to expand our product line with custom rubber toys, Preeminent delivered beyond expectations. Their R&D team suggested improvements to our initial designs that made the toys more durable and appealing. The one-stop sourcing saved us countless hours and reduced our costs significantly."

Emma Rodriguez

PetPaw, Canada

"As a startup, we were worried about minimum order quantities and quality control. Preeminent worked with us to create a phased approach that matched our growth. Their private label option allowed us to launch quickly, and now we're developing fully custom designs. Their communication is always prompt and clear."

Daniel Kim

WoofLion, South Korea

"Preeminent's ability to create multi-material toys that combine rope, plush, and TPR elements has given our brand a competitive edge. Their factory capabilities are impressive, and the quality control is meticulous. Every shipment arrives on time and meets our exact specifications."

Join over 200+ pet brands worldwide who trust Preeminent for their pet supplies manufacturing needs.

Frequently Asked Questions

Common questions about OEM/ODM private label dog toys manufacturing

We offer a comprehensive range of rubber dog toy manufacturing capabilities: Basic Rubber Toy Types: 1.Solid rubber balls in various sizes and textures 2.Rubber rings and discs for fetch and tug play 3.Rubber bones and chew sticks for dental health 4.Hollow treat-dispensing rubber toys 5.Floating rubber toys for water play Interactive Design Features: 1.Textured surfaces for dental cleaning 2.Puzzle toys with treat compartments 3.Multi-component designs with different hardness levels 4.Bounce-optimized toys for interactive play 5.Squeaker-integrated rubber toys Our manufacturing expertise allows us to produce both natural rubber and synthetic rubber (TPR) toys to meet different price points and market preferences. We can customize existing designs with your branding or develop completely new concepts based on your specific requirements.

Rubber dog toys offer several significant advantages for aggressive chewers: Superior Durability Features: 1.High tensile strength that resists tearing 2.Resilient material that returns to shape after biting 3.Non-splintering construction unlike many hard plastic toys 4.Ability to withstand repeated compression forces Safety Benefits: 1.Fewer broken pieces that could be ingested 2.More predictable wear patterns that owners can monitor 3.Flexible material that's gentler on teeth than very hard alternatives 4.Better shock absorption to protect dental health Our premium rubber dog toys are specifically engineered for power chewers with reinforced designs, appropriate density levels, and specialized manufacturing techniques that extend product lifespan. We can customize the hardness and flexibility to match your brand's durability claims and target customer needs.

We utilize several high-quality materials for our dog toys, each offering different benefits: Natural Rubber: 1.Derived from rubber tree sap 2.Excellent elasticity and bounce properties 3.Softer feel with good durability 4.Often preferred for premium and eco-friendly product lines Thermoplastic Rubber (TPR): 1.Synthetic rubber alternative with consistent performance 2.Available in various hardness levels (measured in Shore A) 3.Excellent color stability and design flexibility 4.Cost-effective for complex molded designs Nylon: 1.Extremely durable for power chewers 2.High tensile strength and impact resistance 3.Great for composite toys with rubber components 4.Provides long-lasting durability for aggressive dogs Silicone: 1.Food-grade safety for treat-dispensing toys 2.Heat resistance for dishwasher-safe options 3.Soft texture with good durability 4.Excellent for dental chew toys with gentle texture All our materials undergo rigorous testing for safety compliance with international standards including FDA, REACH, EN71, and pet-specific regulations. We can provide detailed material specifications and safety certifications for your specific market requirements.

Yes, we specialize in creating custom-shaped rubber dog toys through our advanced molding capabilities: Design Possibilities: 1.Brand mascots or logo-shaped toys 2.Themed designs (food items, animals, objects) 3.Seasonally relevant shapes (holiday-themed) 4.Innovative functional designs unique to your brand Our Custom Design Process: 1.Concept development based on your ideas or market research 2.3D modeling and digital rendering for approval 3.Prototype creation and testing for functionality 4.Mold engineering and production Design Considerations We Manage: 1.Ensuring proper wall thickness for durability 2.Optimizing shapes for safe play characteristics 3.Engineering appropriate bite surfaces and textures 4.Incorporating your branding elements seamlessly Our experienced design team can help refine concepts to ensure they're both manufacturable and appealing to dog owners while maintaining the play value and durability dogs require.

TPR (Thermoplastic Rubber) and natural rubber offer different characteristics that affect product performance and positioning: Material Origin: 1.Natural Rubber: Harvested from rubber trees, biodegradable, renewable resource 2.TPR: Synthetic polymer blend manufactured through chemical processes Performance Differences: 1.Elasticity: Natural rubber typically has superior bounce and stretch properties 2.Durability: TPR often provides more consistent wear resistance 3.Temperature Stability: TPR generally performs better in extreme temperatures 4.Aging: Natural rubber may show earlier signs of breakdown from UV exposure Manufacturing Considerations: 1.Color Options: TPR offers broader color possibilities and consistency 2.Design Complexity: TPR allows for more intricate molded details 3.Production Efficiency: TPR typically has faster production cycles Market Positioning: 1.Natural Rubber: Often used for premium, eco-conscious brands 2.TPR: Popular for mainstream products with specific technical requirements and competitive price points We can help you select the right material based on your product concept, price targets, and brand positioning to ensure optimal performance and market fit.

We implement a comprehensive safety assurance system for all our rubber dog toys: Material Safety Testing: 1.Chemical composition analysis for harmful substances 2.Phthalate, BPA, and heavy metal screening 3.Migration testing to simulate saliva contact 4.Compliance verification with FDA, REACH, and pet product regulations Physical Safety Engineering: 1.Size appropriateness evaluations for different dog breeds 2.Choking hazard assessments 3.Sharp edge elimination in the design phase 4.Break-resistance testing under simulated bite force Quality Control During Production: 1.Raw material certification and batch testing 2.In-process inspections for dimensional accuracy 3.Visual and tactile inspections for defects 4.Random sampling for performance testing Documentation and Traceability: 1.Detailed material composition records 2.Batch tracking throughout production 3.Test certificates available for import compliance 4.Material Safety Data Sheets (MSDS) provided as required Our rigorous safety protocols exceed industry standards and help protect both your brand reputation and the dogs who use our products.

We offer extensive customization options for rubber dog toys: Color Customization: 1.Pantone color matching to your brand palette 2.Multi-color molding capabilities 3.Marbled or speckled color effects 4.Color gradients and transitions Surface Treatments: 1.Textured surfaces (ridges, bumps, nubs) 2.Polished or matte finish options 3.Dual-density molding for varied texture zones 4.Grip-enhancing patterns Branding Elements: 1.Molded-in logos or text 2.Debossed or embossed design elements 3.Co-molded brand badges in contrasting colors 4.Custom packaging design services Functional Customization: 1.Scent infusion (vanilla, mint, bacon, etc.) 2.Specialized internal features (wobble weights, squeakers) 3.Treat-dispensing mechanism variations 4.Interactive component designs Our engineering team can develop prototypes to test different customization options, ensuring the final product perfectly represents your brand while meeting all functional requirements.

Our rubber dog toy production process follows these key stages: Design & Development (2-3 weeks): 1.Concept finalization and technical drawing creation 2.Material selection and specification 3.3D modeling and digital rendering 4.Design review and approval Tooling & Mold Creation (3-4 weeks): 1.Mold design engineering 2.CNC machining of steel molds 3.Mold testing and refinement 4.Sample production approval Mass Production (2-4 weeks, depending on quantity): 1.Raw material preparation and quality verification 2.Injection molding or compression molding 3.Cooling and trimming operations 4.Assembly of multiple components (if applicable) Quality Control & Finishing: 1.100% visual inspection 2.Dimensional verification 3.Performance testing (bounce, flexibility, etc.) 4.Cleaning and preparation for packaging Packaging & Shipping: 1.Application of labels or packaging inserts 2.Packaging according to specifications 3.Carton packing and palletizing 4.Shipping documentation preparation Throughout this process, we maintain constant communication and provide regular updates, including production photos and quality reports to ensure transparency.

Our minimum order quantities for rubber dog toys vary based on the type of customization: For Standard Products with Logo Customization: 1.Typically 1,000-2,000 pieces per design For Custom-Designed Products: 1.Usually 1,000-3,000 pieces per design 2.Higher quantities may be required for very complex designs or special materials For Multi-Component Rubber Toys: 1.Generally 3,000-5,000 pieces due to additional tooling requirements Factors that influence MOQ include: 1.Mold complexity and production costs 2.Color changes required 3.Material specifications 4.Packaging requirements We understand business growth stages and can sometimes offer flexible solutions such as phased production runs or combined shipping with other products to make custom rubber toys accessible to emerging brands. Contact us to discuss your specific project requirements for detailed MOQ information.

Our rubber dog toys are engineered for exceptional durability that often exceeds competitor offerings: Material Advantages: 1.Premium-grade rubber compounds with optimized formulations 2.Higher rubber content percentage than industry standard 3.Specialized additives for UV resistance and durability 4.Careful balance between flexibility and strength Manufacturing Superiority: 1.Precise temperature control during molding for optimal curing 2.Higher pressure molding techniques for better material density 3.Advanced mold design that eliminates weak points 4.Stringent quality control that catches potential defects Design Engineering: 1.Strategic wall thickness distribution for maximum strength 2.Reinforced stress points based on bite analysis 3.Rounded edges that reduce tear initiation 4.Calculated density variations for chew resistance Our durability testing includes: 1.Accelerated aging simulations 2.Mechanical stress testing with specialized equipment 3.Real-world testing with different dog breeds and play styles 4.Comparative analysis against leading market competitors Many of our B2B clients specifically choose us because our rubber toys deliver longer lifespans and better performance, which leads to higher customer satisfaction ratings and fewer returns - ultimately protecting your brand reputation and improving profitability.

Connect Your Brand With Pet Parents

Jolin

Jasmine

Bella

Sara

Kevin

Jackson

You are one step closer to creating amazing pet products for your brand.