Are You Looking For

Professional Dog Toys Manufacturer?

We provide one-stop solutions for your private label OEM/ODM dog toys production, making it easy to build your own brand.

Your Brand, Your Dog Toys, Expertly Made

We manufacture a vast range of dog toys (plush dog toys,rubber dog toys,rope dog toys & more). Choose your perfect manufacturing path:

Plush Dog Toys

"Premium plush dog toys that combine irresistible softness with surprising durability - the cuddly bestsellers your inventory needs."

View Details

Rubber TPR Nylon Dog Toys

"Virtually indestructible rubber dog toys that outlast the competition - the high-margin, low-return products smart retailers stock first."

View Details

Rope Dog Toys

"Multi-textured rope dog toys that clean teeth while they entertain - the dual-purpose products that drive repeat customer satisfaction."

View Details

Latex Dog Toys

"High-visibility latex dog toys with irresistible squeakers - the impulse purchase that transforms your checkout area into a profit center."

View Details

Dog Puzzle Toys

"Ingenious puzzle toys that challenge minds while preventing destructive behaviors - the premium solution savvy pet parents specifically request by name."

View Details

Dog Tennis Balls

"Premium-grade dog tennis balls with enhanced bounce technology - the everyday essential that drives consistent year-round sales in any economy."

View Details

Dog Tug Toy

"Professionally-designed dog training toys that reinforce positive behaviors - the specialty items that transform one-time buyers into loyal brand advocates."

View Details

Treat Dispensing Dog Toys

"Strategically-engineered treat dispensing toys that create a captive market for consumables — the essential hardware that unlocks a powerful, recurring revenue stream from your proprietary, high-margin treat lines."

Manufacturing Excellence

Choose your perfect path to market success

Private Label our ready-to-ship designs

Over 10,000 available designs ready for your branding. Quick turnaround and minimal setup costs.

Go Fully Custom (ODM)

Unique molds, fabrics, and innovative features developed just for you. Bring your vision to life with our expertise.

One-on-One Partnership

We partner with you one-on-one to bring your vision to life. Explore our flexible manufacturing levels below.

Ideas + Manufacturing = Success

Your Custom pet supplies Ideas + Our Expert Manufacturing = Market Success. We turn concepts into profitable products.

Dedicated OEM/ODM Support

We specialize in bringing brand owners' unique pet supplies concepts to life with consistent quality and dedicated end-to-end support.

Boost Your Margins

Get Factory-Direct Pricing. Cut out middlemen and maximize your profit potential with our competitive manufacturing rates.

Hey there! Have some innovative ideas been popping into your head?

Why not bring them to the table? Let's chat and explore the possibilities together. Our team of experts is ready to transform your dog toys concepts into reality.

Ultimate Guide to Dog Toy Custom and Wholesale

Dog Toy Market, Manufacturing, and Sourcing Guide

Master the complete dog toy manufacturing process from market analysis to production with our comprehensive 12-chapter guide covering everything you need to know as a professional buyer and brand owner.

The Dog Toy Market Overview

Dog Toy Functions and Benefits

Dog Toy Materials and Components

Types of Dog Toys

Dog Toy Manufacturing Methods

OEM vs ODM Dog Toy Services

Dog Toy Design Considerations

Packaging and Branding for Dog Toys

Dog Size and Toy Selection Guide

Custom and Wholesale Considerations

Custom Dog Toy Cost Analysis

Choose Your Dog Toy Manufacturer

Ready to start your dog toy manufacturing journey?

Why Dog Toys Are the Most Profitable Pet Product Investment

Global Dog Toy Market Size and Growth Trends

The dog toy market shows strong growth momentum driven by rapid pet economy development. Reaching $4.5 billion in 2025 with steady compound annual growth, the market demonstrates diversified characteristics as pet owners increasingly value their dogs' entertainment and mental health needs.

Consumer Purchasing Behavior Changes

Modern pet owners are shifting from basic functional needs toward emotional value pursuit. Consumers now prioritize safety, educational value, and interactivity in dog toys. Online purchasing channels and social media influence have made decision-making processes more complex and personalized.

Popular Dog Toy Product Trends

Smart interactive toys and multifunctional training toys dominate current trends. Eco-friendly chew toys see surging demand, while educational puzzle toys gain popularity. Personalized customization and seasonal themed toys are pioneering new market segments.

Market Opportunities and Challenges

Companies entering this industry must understand the market's dual nature. Success requires seizing consumption upgrade opportunities and technological innovation benefits while meeting evolving market demands. This chapter provides comprehensive analysis and strategic references for industry participants.

Top Product Categories

Dog Toy Functions and Benefits

What are the benefits of dog toys

Benefits for Dogs

Dog toys provide essential functions for your dog's physical and mental wellbeing. These include entertainment and mental stimulation to prevent boredom, dental health maintenance through chewing activities, anxiety relief and stress reduction for nervous pets, exercise promotion for physical fitness, and behavioral training support for obedience and intelligence development.

Benefits for Brands

Dog toys represent a highly profitable business opportunity in the rapidly expanding pet market. With consistent market growth and substantial profit margins, brands can capitalize on high repeat purchase rates as toys require regular replacement. The visual appeal of dog toys creates powerful social media marketing opportunities - unique branded toy designs encourage pet parents to share photos and videos across platforms, generating organic brand exposure and viral marketing potential. This combination of strong economics and natural shareability makes dog toys an ideal product category for building brand recognition and customer loyalty.

Five Major Dog Toy Functions

Dog Breed & Age Specific Toy Requirements

| Dog Category | Recommended Toys | Primary Benefits | Safety Considerations |

|---|---|---|---|

| Puppies (0-12 months) | Soft plush, teething toys, puzzle balls | Teething relief, basic training | Non-toxic, size appropriate |

| Small Breeds | Mini rope toys, small rubber balls | Proportional exercise, dental care | Avoid choking hazards |

| Large Breeds | Heavy-duty ropes, large chew toys | Strength training, jaw exercise | Durable materials, proper sizing |

| Active Breeds | Fetch toys, interactive puzzles | Energy release, mental stimulation | Weather resistant, easy to clean |

| Senior Dogs (7+ years) | Soft comfort toys, gentle puzzles | Comfort, cognitive maintenance | Gentle on joints, easy to grip |

Dog Toy Materials & Components

Material Selection by Product Type

1. Plush Dog Toys

Fabrics:

- • Crystal Super Soft

- • Short Plush

- • Long Plush

- • Canvas

- • Oxford Fabric

Filling:

- • PP Cotton

- • Squeaker

- • Crinkle Material

- • Foam

2. Chew Dog Toys

Materials:

- • Natural Rubber

- • TPR

- • Nylon

- • Latex

- • Cotton Rope

3. Tug Dog Toys

Materials:

- • Jute

- • Ripstop Fabric

- • Nylon

- • Leather

4. Fetch & Water Toys

Materials:

- • Natural Rubber

- • TPR

- • Oxford Fabric

- • EVA

- • ETPU

5. Puzzle & Food Dispensing Toys

Materials:

- • ABS

- • PP

Material Properties Comparison

| Material | Chew Resistance | Cleaning Ease | Cost Range | Suitable Dog Size |

|---|---|---|---|---|

| Natural Rubber | High | Easy | $2.5-$5 | All Sizes |

| TPR | Medium | Easy | $1.5-$3 | Small-Medium |

| Nylon | Very High | Medium | $3-$5 | Medium-Large |

| Cotton Rope | Medium | Hard | $0.5-$2 | All Sizes |

| Plush Fabric | Low | Medium | $1.5-$4 | Small-Medium |

Selection by Target Market

Premium Market

Natural rubber, organic cotton, high-grade plush fabrics for safety-conscious consumers

Mid-Range Market

TPR, standard plush, nylon rope combinations for balanced quality and cost

Budget Market

Basic cotton rope, standard synthetic materials for cost-effective options

Selection by Price Positioning

High-End ($15-30+)

Premium natural materials, specialized components, eco-friendly options

Mid-Range ($5-15)

Quality synthetic materials, durable construction, functional features

Entry-Level ($1-5)

Basic materials, simple construction, essential functionality

Types of Dog Toys

1. Chew Toys

Function: Satisfy dogs' chewing needs and help with teeth grinding, promoting dental health and preventing destructive chewing behavior.

Product Types: Rubber bones, rope knot toys, nylon toys, dental chews, and textured chewing surfaces.

Suitable Materials: Natural rubber, TPR, cotton rope, nylon for durability and safety.

2. Puzzle Toys

Function: Train dogs' thinking and intellectual development, providing mental stimulation and preventing boredom-related behaviors.

Product Types: Food dispensing toys, puzzle toys, hide & seek toys, treat-releasing mechanisms.

Suitable Materials: ABS plastic, PP, wood for structural integrity and easy cleaning.

3. Interactive Toys

Function: Owner and dog play together, strengthen bonding and provide physical exercise through shared activities.

Product Types: Frisbees, tug rope toys, balls, fetch toys, flying discs, and throwing sticks.

Suitable Materials: Rubber, nylon, cotton rope, EVA foam for outdoor durability.

4. Comfort Toys

Function: Relieve anxiety, provide security and companionship, especially beneficial for puppies and nervous dogs.

Product Types: Plush toys, pillow-type toys, heartbeat sound toys, cuddle companions.

Suitable Materials: Crystal super soft fabric, long plush, PP cotton filling for softness and comfort.

5. Training Toys

Function: Assist training, develop skills and obedience, supporting professional training programs and behavioral modification.

Product Types: Tug-of-war toys, snuffle mats, agility equipment, reward-based training tools.

Suitable Materials: Nylon, ripstop fabric, jute, rubber for training durability and grip.

Top Product Categories

Market Insights

Dog Toy Manufacturing Methods

›› 1. Raw Materials and Testing

Our factory sources premium fabrics, PP cotton filling, and food-grade rubber materials, conducting 100% safety testing on each type of raw material to ensure they meet international pet safety standards before proceeding to the next stage. All plush and rubber materials are verified to be non-toxic and pet-safe.

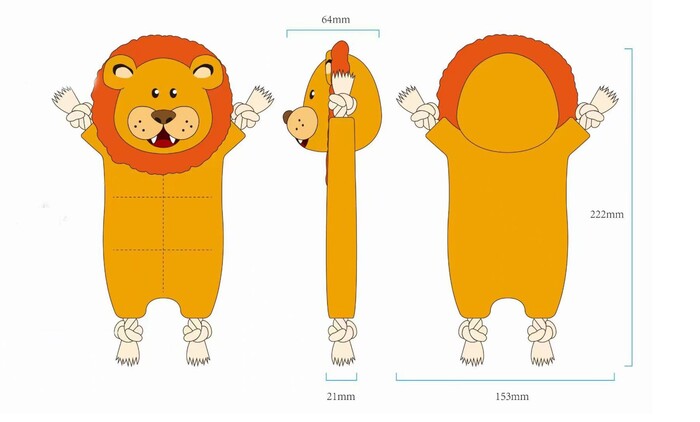

›› 2. Custom Design and Prototyping

Through our professional design team and ODM capabilities, we create unique concepts for both plush and rubber dog toys. Our sampling room ensures accuracy in pattern drawing, cutting, and mold development, guaranteeing consistency and precision in each custom product design across different material categories.

›› 3. Material Preparation and Processing

For Plush Toys: Our PP cotton preparation ensures toys are soft and safe, with optimal stuffing techniques for lasting comfort. For Rubber Toys: We prepare food-grade rubber compounds with precise mixing ratios to achieve the ideal texture, durability, and bite resistance suitable for different dog breeds and play behaviors.

›› 4. Cutting, Molding and Detailed Crafting

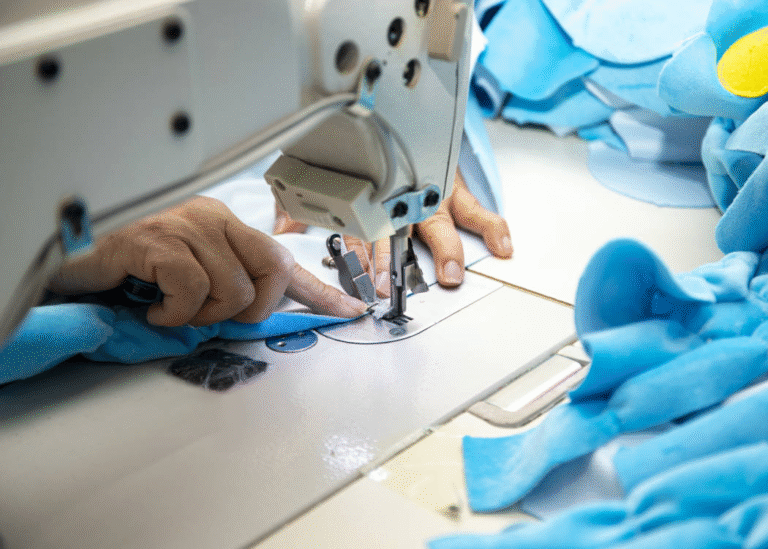

Plush Production: We utilize advanced laser cutting and automatic cutting tables for diverse fabric shapes, plus precision embroidery machines for custom logos. Rubber Production: We employ injection molding and compression molding techniques to create durable rubber toys with consistent quality. Both processes boost production efficiency while meeting specific client requirements.

›› 5. Quality Assembly and Safety Inspection

Our comprehensive quality control process includes reinforced stitching for plush toys and durability testing for rubber toys. We conduct thorough safety checks including needle detection, bite-resistance testing, and toxicity verification to ensure each toy meets the highest safety standards for pet play.

›› 6. Packaging and Finishing

In the final steps, we meticulously clean both plush and rubber toys, attach custom tags with client branding, and package them according to specifications. We ensure products are ready for shipment with proper labeling and packaging that reflects our clients' brand identity across both product categories.

OEM vs ODM Dog Toy Services

Understanding the difference between OEM and ODM services helps you choose the right manufacturing partnership for your dog toy business goals.

OEM Service

Private Label Dog Toy Customization

What is OEM Service?

OEM (Original Equipment Manufacturer) service allows you to customize existing dog toy designs with your brand identity. We manufacture proven products under your private label, ensuring consistent quality and faster time-to-market.

Key Features:

- Custom logo and branding on existing designs

- Personalized packaging and labels

- Color and material variations

- Lower minimum order quantities

- Faster production timeline

Best For:

Retailers, distributors, and brands looking to quickly enter the market with proven products under their own brand identity.

ODM Service

Original Design Dog Toy Development

What is ODM Service?

ODM (Original Design Manufacturer) service provides complete custom dog toy development from concept to production. We design unique products based on your specifications, creating exclusive toys that differentiate your brand in the market.

Key Features:

- Complete custom design from scratch

- Unique product development and innovation

- Exclusive designs and features

- Full intellectual property ownership

- Comprehensive design consultation

Best For:

Brands seeking unique market positioning with innovative, exclusive dog toy designs that cannot be replicated by competitors.

Service Comparison Overview

| Comparison Factor | OEM Service | ODM Service |

|---|---|---|

| Development Time | 2-4 weeks | 6-12 weeks |

| Minimum Order Quantity | 500-1,000 pcs | 1,000-3,000 pcs |

| Design Uniqueness | Limited customization | Completely unique |

| Investment Level | Lower | Higher |

| Market Risk | Lower (proven products) | Higher (new products) |

| Profit Potential | Standard margins | Premium margins |

| IP Ownership | Shared/Limited | Full ownership |

Dog Toy Design Considerations

Successful dog toy design requires balancing multiple factors from canine behavior to manufacturing efficiency, ensuring products that are safe, engaging, and commercially viable.

Dog Behavior Psychology Considerations

Understanding canine instincts is fundamental to effective toy design. Dogs have natural behaviors including hunting, chewing, digging, and social play that should be incorporated into toy functionality.

Toys should trigger positive behavioral responses such as prey drive for fetch toys, comfort-seeking for plush toys, and problem-solving for puzzle toys. Design elements like movement, texture, and hiding capabilities tap into these natural instincts.

Different Breed Characteristics Adaptation

Breed-specific traits significantly impact toy preferences and safety requirements. Terriers need durable toys for intense play, while retrievers prefer soft-mouth friendly materials that won't damage their gentle bite.

Jaw strength, play style, and energy levels vary dramatically between breeds. Design considerations include size scaling, material hardness, and interaction complexity tailored to specific breed characteristics and typical owner demographics.

Bite-Resistant Durability Design

Durability engineering focuses on stress distribution and material selection to withstand repetitive chewing forces. Critical stress points require reinforcement through design geometry and material density variations.

Advanced rubber compounds, textile weaving patterns, and multi-layer construction techniques extend product lifespan. Testing protocols simulate months of chewing to validate durability claims and prevent premature failure.

Fun and Appeal Factors (Color, Texture, Sound)

Visual and tactile elements drive initial attraction and sustained engagement. High-contrast colors, varied textures, and interactive sounds stimulate different sensory responses that maintain long-term interest.

Strategic use of squeakers, crinkle materials, and textural variations creates multi-sensory experiences. Color psychology affects both dog engagement and owner purchasing decisions, requiring balance between canine preference and market appeal.

Size Safety Design Standards

Proper sizing prevents choking hazards while ensuring effective functionality. Toys must be large enough to prevent swallowing but appropriately scaled for comfortable gripping and manipulation.

Safety standards require specific size ratios relative to dog weight and mouth dimensions. Detachable components need additional safety considerations, including attachment strength and individual part sizing protocols.

Cost-Effectiveness Balance

Successful designs optimize material costs, manufacturing complexity, and performance requirements to achieve target price points while maintaining quality standards and safety compliance.

Value engineering considers component costs, production efficiency, and market positioning to maximize profitability. Design decisions must balance premium features with mass market accessibility for optimal commercial success.

Design Priority Checklist

Size Guidelines

Material Durability Scale

Packaging and Branding for Dog Toys

Effective packaging design drives purchase decisions while building brand recognition. Strategic packaging solutions balance cost efficiency with marketing impact to maximize retail success.

Standard Dog Toy Packaging Options

Basic packaging solutions include clear polybags with header cards, simple cardboard boxes, and shrink-wrap options. These cost-effective choices provide product protection while allowing clear product visibility for consumer evaluation.

Standard formats typically include hanging bags for retail hooks, window boxes for shelf display, and bulk packaging for wholesale distribution. Each option balances protection, visibility, and cost efficiency for different market channels.

Custom Packaging Design (Brand Elements & Culture)

Custom packaging transforms products into brand ambassadors through strategic visual design. Incorporating brand colors, mascots, and messaging creates emotional connections that drive consumer preference and premium pricing opportunities.

Brand culture integration includes lifestyle imagery, value propositions, and personality elements that resonate with target demographics. Custom die-cuts, special finishes, and unique structural designs differentiate products in competitive retail environments.

Brand Identity Application

Consistent brand application across all packaging elements reinforces recognition and builds trust. Logo placement, typography consistency, and color palette adherence create cohesive brand experiences that enhance perceived value.

Strategic brand positioning includes tagline integration, product benefit highlighting, and quality assurance messaging. Professional application ensures packaging supports overall brand strategy and marketing objectives across all touchpoints.

Retail Display Packaging

Retail-optimized packaging maximizes shelf impact through strategic sizing, graphics placement, and display functionality. Packages must compete for attention while conveying product benefits within seconds of consumer viewing.

Display considerations include hanging capabilities, stacking stability, and planogram compatibility. Effective retail packaging drives impulse purchases through compelling visuals and clear value communication at the point of sale.

Packaging Cost Analysis

Packaging costs typically represent 8-15% of total product cost, varying by complexity and volume. Basic packaging solutions start at $0.1-0.30 per unit, while premium custom options range from $0.50-1.50 per unit.

Cost optimization strategies include material selection, printing specifications, and volume commitments. ROI analysis should consider packaging's impact on perceived value, retail acceptance, and long-term brand building versus incremental cost increases.

Popular Packaging Types

Packaging Cost Range

Custom Packaging Benefits

Retail Size Standards

Dog Size and Toy Selection Guide

Proper toy sizing ensures safety and engagement across all dog breeds and life stages. Understanding size-specific requirements helps manufacturers develop targeted product lines for optimal market success.

Small Dog Toy Recommendations (Chihuahua, Yorkshire Terrier, etc.)

Small dogs (under 25 pounds) require appropriately scaled toys that prevent choking hazards while providing adequate stimulation. Recommended toys include mini rope toys 4-6 inches in length, small rubber balls 2-3 inches in diameter, and lightweight plush toys.

Material considerations include softer rubber compounds to protect delicate teeth and gums. Avoid toys with small detachable parts, and ensure all components are larger than the dog's throat diameter. Interactive puzzle toys should have appropriately sized treat compartments for small kibble.

Medium Dog Toy Recommendations (Corgi, Border Collie, etc.)

Medium dogs (25-60 pounds) benefit from versatile toys that balance durability with engagement. Recommended sizes include rope toys 8-12 inches, rubber balls 3-4 inches in diameter, and multi-textured chew toys with varied hardness levels.

This size category often includes highly intelligent breeds requiring mental stimulation through puzzle toys and interactive games. Tug toys should accommodate both solo play and human interaction, with comfortable grip areas for owners and durable construction for energetic play sessions.

Large Dog Toy Recommendations (Golden Retriever, German Shepherd, etc.)

Large dogs (60+ pounds) require robust toys that withstand powerful jaws and energetic play. Recommended products include heavy-duty rope toys 12+ inches, large rubber balls 4-6 inches in diameter, and reinforced chew toys with dense construction.

Safety considerations include extra-strong stitching for plush toys and impact-resistant materials for fetch toys. Large breeds often have strong retrieval instincts, requiring toys designed for outdoor use with weather-resistant materials and high visibility colors for easy location.

Puppy vs Adult Dog Toy Differences

Puppy toys prioritize teething relief with softer materials and varied textures to soothe sore gums. Adult dog toys focus on mental stimulation, exercise promotion, and long-term durability. Sizing considerations change dramatically as puppies grow rapidly during their first year.

Developmental differences include attention span variations, with puppies requiring immediate gratification toys while adults benefit from complex puzzle challenges. Material safety standards are stricter for puppies due to their tendency to swallow foreign objects and developing digestive systems.

Quick Size Reference

Popular Breeds by Size

Small

Chihuahua, Yorkshire Terrier, Pomeranian, Maltese

Medium

Corgi, Border Collie, Beagle, Cocker Spaniel

Large

Golden Retriever, German Shepherd, Labrador, Rottweiler

Age Considerations

Size Safety Correspondence Table

| Dog Size Category | Weight Range | Recommended Toy Size | Ball Diameter | Rope Length | Safety Considerations |

|---|---|---|---|---|---|

| Extra Small | Under 10 lbs | 2-4 inches | 1.5-2 inches | 3-5 inches | No small parts |

| Small | 10-25 lbs | 4-6 inches | 2-3 inches | 6-8 inches | Soft materials |

| Medium | 25-60 lbs | 6-10 inches | 3-4 inches | 8-12 inches | Balanced durability |

| Large | 60-90 lbs | 10-14 inches | 4-5 inches | 12-16 inches | Heavy-duty materials |

| Extra Large | 90+ lbs | 14+ inches | 5-6 inches | 16+ inches | Maximum strength |

Custom and Wholesale Dog Toy Considerations

Successful dog toy business requires strategic planning across multiple dimensions. Understanding these key considerations helps brands make informed decisions for sustainable growth and market success.

Target Dog Owner Analysis

Understanding target demographics drives product development and marketing strategy. Key segments include premium pet parents seeking quality products, budget-conscious families prioritizing value, and specialty buyers focused on specific breeds or training needs.

- • Age demographics and purchasing power

- • Pet ownership experience levels

- • Geographic market preferences

- • Channel preferences (online vs retail)

Safety Compliance Requirements

Regulatory compliance ensures market access and consumer safety. Requirements vary by target markets, with strict standards for materials, testing protocols, and labeling requirements that must be maintained throughout production.

- • ASTM F963 toy safety standards

- • Non-toxic material certifications

- • Choking hazard assessments

- • International market compliance

Seasonal Sales Considerations

Sales patterns fluctuate significantly throughout the year, requiring strategic inventory planning and product positioning. Peak seasons drive 60-70% of annual sales, with specific product categories performing differently across seasons.

- • Holiday gift season (Oct-Dec): +150% sales

- • Spring adoption season (Mar-May): +75% sales

- • Summer outdoor toys: High demand

- • Winter comfort toys: Moderate demand

Cost Control and Profit Margins

Maintaining healthy margins requires balancing quality expectations with cost efficiency. Successful brands typically achieve 45-65% gross margins through strategic sourcing, efficient production, and value-based pricing strategies.

- • Material cost optimization: 30-40% of total cost

- • Production efficiency improvements

- • Volume discount negotiations

- • Value engineering opportunities

Supply Chain Stability

Reliable supply chains prevent stock-outs and maintain consistent quality standards. Diversified supplier networks and strategic partnerships ensure business continuity during market disruptions and seasonal demand fluctuations.

- • Multiple supplier qualification

- • Raw material inventory management

- • Quality consistency monitoring

- • Backup production capabilities

Customization Requirements

Brand differentiation through customization creates competitive advantages and premium pricing opportunities. Flexible manufacturing capabilities accommodate varying customization levels from simple branding to complete design modifications.

- • Logo and branding application

- • Color and material variations

- • Size and feature modifications

- • Packaging customization options

Delivery Timeline Requirements

Meeting delivery commitments requires efficient production planning and logistics coordination. Lead times vary significantly between standard products (2-4 weeks) and custom developments (6-12 weeks), requiring careful scheduling.

- • Standard products: 2-4 weeks lead time

- • Custom products: 6-12 weeks development

- • Seasonal preparation: 3-6 months advance

- • Rush order capabilities and costs

After-Sales Support

Comprehensive support services build long-term partnerships and customer loyalty. Professional support includes technical assistance, quality issue resolution, and business development guidance for sustained success.

- • Quality issue response and resolution

- • Product development consultation

- • Market trend insights and analysis

- • Business growth support services

Strategic Success Framework

Successful dog toy businesses balance these eight critical considerations to create sustainable competitive advantages. Strategic planning across all dimensions ensures long-term profitability and market leadership in the dynamic pet products industry.

Custom Dog Toy Cost Comparison Analysis

Understanding material characteristics and customization requirements helps make informed decisions for product development, balancing market demand with manufacturing feasibility and cost efficiency.

Comprehensive Material Analysis for Custom Dog Toys

*Analysis based on market data and manufacturing experience

| Material Type | Market Popularity | Common Toy Types | Durability | Custom Cost | Cost Explanation |

|---|---|---|---|---|---|

|

Plush Fabric

|

Highest | Comfort toys, cuddle companions, squeaky toys, character toys | Medium | Lowest | Only requires design and pattern making. Low material costs and simple manufacturing process. |

|

Natural Rubber

|

High | Chew toys, dental toys, bouncing balls, interactive toys | Very High | Medium-High | Requires custom mold development. Higher tooling costs due to precision molding requirements. |

|

TPR

|

Medium-High | Flexible chew toys, soft balls, squeaky toys, fetch toys | High | Medium-High | Custom molding required. Moderate tooling costs with efficient processing capabilities. |

|

Cotton Rope

|

Medium | Tug toys, braided toys, knot toys, dental rope toys | Medium | Lowest | Simple braiding and knotting techniques. No molding required, just pattern design and manual assembly. |

|

Natural Latex

|

Medium-Low | Squeaky toys, novelty shapes, soft chew toys, interactive toys | Medium | Medium | Requires molding but uses plaster molds. Lower tooling costs compared to rubber/TPR. |

|

Nylon

|

Medium-Low | Heavy-duty chew toys, bones, dental toys, training toys | Very High | Medium-High | Custom molding with specialized equipment. Higher precision requirements for safety and durability. |

|

Plastic (ABS/PP)

|

Medium | Puzzle toys, treat dispensers, interactive feeders, multi-part toys | High | Highest | Multiple components require separate molds. One toy may need 3-5 different molds, significantly increasing tooling costs. |

Market Popularity Insights

Top Performers

Plush toys dominate with highest consumer preference due to emotional appeal and comfort factor.

Rubber toys maintain strong market position for durability-focused consumers.

Niche Markets

Nylon & Plastic toys serve specialized needs but have limited mass appeal.

Latex toys face declining popularity due to allergy concerns.

Strategic Considerations

Focus on plush and rubber categories for maximum market penetration and volume sales.

Cost Optimization Strategies

Low-Cost Entry Points

Plush & Rope toys offer quickest market entry with minimal tooling investment.

Ideal for testing market response and building initial product lines.

Medium Investment Options

Rubber & TPR toys require mold investment but offer higher margins and durability positioning.

Latex toys offers compromise with lower molding costs using plaster molds.

High-Investment Considerations

Plastic toys require significant upfront investment but may offer unique positioning for interactive/puzzle categories.

Strategic Material Selection Framework

Market Entry Strategy

Start with plush dog toys for immediate market acceptance and low investment, then expand to rubber for premium positioning

Portfolio Balance

Combine high-volume plush products with specialized durable options to maximize market coverage and profitability

Innovation Opportunities

Explore plastic interactive puzzle dog toys for differentiation, but validate market demand before significant mold investment

How to Choose Your Dog Toy Manufacturer

Selecting the right manufacturing partner is crucial for business success. This comprehensive evaluation framework helps assess potential manufacturers across key performance dimensions for informed decision-making.

Comprehensive Manufacturer Assessment Framework

*Use this framework to systematically evaluate potential manufacturing partners

| Evaluation Criteria | Key Assessment Points | What to Look For | Red Flags to Avoid | Priority Level |

|---|---|---|---|---|

|

Manufacturing Capability Assessment

|

|

Modern machinery, multiple material expertise, documented capacity metrics, expansion capabilities | Outdated equipment, limited material options, vague capacity claims, no growth planning | Critical |

|

Dog Toy Professional Experience

|

|

5+ years pet focus, established brand partnerships, trend awareness, regulatory knowledge | General toy manufacturer, no pet expertise, limited references, outdated knowledge | Critical |

|

Quality Control System

|

|

Documented QC systems, regular testing, low defect rates, transparency in quality metrics | No formal QC system, inconsistent testing, high returns, quality issue defensiveness | Critical |

|

Design Development Capability

|

|

Dedicated design team, rapid prototyping, creative solutions, strong IP protocols | No design capability, outsourced development, limited creativity, weak IP protection | High |

|

Safety Certification Credentials

|

|

ASTM, EN71, CPSIA compliance, current certificates, audit trails, complete documentation | Missing certifications, expired documents, audit failures, incomplete compliance records | Critical |

|

Customer Service Level

|

|

24-hour response, dedicated account management, proactive communication, solution-oriented | Slow responses, language barriers, reactive approach, frequent miscommunications | High |

|

Supply Chain Management

|

|

Diversified suppliers, inventory buffers, logistics partnerships, contingency planning | Single-source dependencies, frequent stockouts, logistics issues, no backup plans | Medium |

Manufacturer Evaluation Checklist

Essential Questions to Ask

Partner Selection Framework

Critical Must-Haves

- • Pet toy manufacturing experience (5+ years)

- • Valid safety certifications

- • Documented quality control system

- • Adequate production capacity

Important Considerations

- • Design and development capabilities

- • Communication and service quality

- • Competitive pricing structure

- • Geographic and cultural fit

Value-Added Benefits

- • Innovation and trend awareness

- • Comprehensive service offerings

- • Strong long-term partnership potential

- • Continuous improvement commitment

Making the Final Decision

Due Diligence Process

Conduct thorough evaluation, request samples, check references, and visit facilities when possible

Test Partnership

Start with small orders to evaluate performance before committing to larger volumes or exclusive arrangements

Long-term Partnership

Build strategic relationships with manufacturers who demonstrate reliability, growth potential, and shared values

Manufacturing That Scales With Your Pet Brand: Find Your Perfect Fit

We understand that pet businesses operate at different phases – whether you're a startup, growing, or an established brand. That's why we offer flexible manufacturing paths designed to meet your specific needs:

Level 1: Private Label Our Stock

Fast Launch: Select from our 10,000+ unique, ready-to-manufacture product designs.

Your Branding: We add your custom swing tags, boxes, stickers, or backboards. Perfect for speed to market, ideal for startups.

Level 2: Modify Existing Designs

Enhanced Branding: Modify stock items without new molds.

Examples: Stitch your logo onto collars or beds, laser your design onto bowls. Great for growing businesses wanting unique touches.Perfect for adding unique touches efficiently.

Level 3: Full Custom Design & Manufacturing (ODM)

Unique Products: Partner with us one-on-one to design and create entirely new, innovative pet products from scratch.

Capabilities:Leverage our full design, injection molding, and cut & sew expertise for market-leading items. Perfect suited for mature brands.

Ready to Learn More? Contact Us to discuss your specific project needs.

Our Manufacturing Facility

Take a virtual tour of our state-of-the-art pet supplies manufacturing facility where quality and innovation come together to create premium products for your brand.

Ready to Start Your Project?

Experience our world-class manufacturing capabilities firsthand. From concept to delivery, we're your trusted partner in creating premium pet products.

What Our Clients Say

Hear from pet brand owners who've partnered with us for their custom pet products manufacturing needs.

Johnson

PawPerfect, USA

"Preeminent transformed our rough sketches into the most adorable plush toys our customers have ever seen. Their attention to detail and quality control is exceptional. We've been working together for 3 years now, and they've become an essential partner for our brand's growth."

Mark Thompson

BarkBoy, Australia

"When we needed to expand our product line with custom rubber toys, Preeminent delivered beyond expectations. Their R&D team suggested improvements to our initial designs that made the toys more durable and appealing. The one-stop sourcing saved us countless hours and reduced our costs significantly."

Emma Rodriguez

PetPaw, Canada

"As a startup, we were worried about minimum order quantities and quality control. Preeminent worked with us to create a phased approach that matched our growth. Their private label option allowed us to launch quickly, and now we're developing fully custom designs. Their communication is always prompt and clear."

Daniel Kim

WoofLion, South Korea

"Preeminent's ability to create multi-material toys that combine rope, plush, and TPR elements has given our brand a competitive edge. Their factory capabilities are impressive, and the quality control is meticulous. Every shipment arrives on time and meets our exact specifications."

Join over 200+ pet brands worldwide who trust Preeminent for their pet supplies manufacturing needs.

Frequently Asked Questions

Common questions about OEM/ODM private label dog toys manufacturing

How do I order custom dog toys from a manufacturer in China?

What is the minimum order quantity (MOQ) for custom dog toys?

How do I create private label dog toys for my brand?

How much does it cost to manufacture dog toys in China?

How long does it take to manufacture custom dog toys?

What materials are best for durable dog toys?

Can you help design dog toys for my brand?

Can I customize packaging for my private label dog toys?

What quality control measures are used for dog toy manufacturing?

How are shipping and logistics handled for dog toys manufactured in China?

Connect Your Brand With Pet Parents

Jolin

Jasmine

Bella

Sara

Kevin

Jackson

You are one step closer to creating amazing pet products for your brand.