Choosing between plush,rubber, nylon, or TPR for your new dog toy line? This single decision impacts your costs, brand reputation, and sales. Let’s make the right choice together.

The best material for a dog toy depends entirely on its intended purpose and your target customer. For extreme chewers, nylon and dense natural rubber are ideal. For interactive play and training, TPR and cotton rope excel. For comfort and light play, plush and fabric are perfect choices.

Choosing the right material is one of the most critical decisions you’ll make when developing a pet product. It impacts everything from safety and durability to cost and brand perception. This decision is about more than just the dog; it’s about building a successful product line for your business. We want to walk you through how we approach this challenge, using our experience to guide you to the perfect choice for your brand. Let’s dive into the specifics.

What material is used in dog toys?

Confused by the endless material options for dog toys? Each has unique properties, costs, and manufacturing needs, making the choice overwhelming. We can clarify the best use for each.

The most common dog toy materials include natural rubber, TPR, nylon, plush fabrics, and cotton rope. Each serves a different function, from extreme durability for power chewers to soft textures for comfort, providing a wide range of options for any product line.

As manufacturers, we see materials as the foundation of a product’s success. It’s not just about what a material is, but what it can do for your product and brand. We work with these materials every day, so we understand their nuances from a technical and business perspective. Let’s break down the most common options.

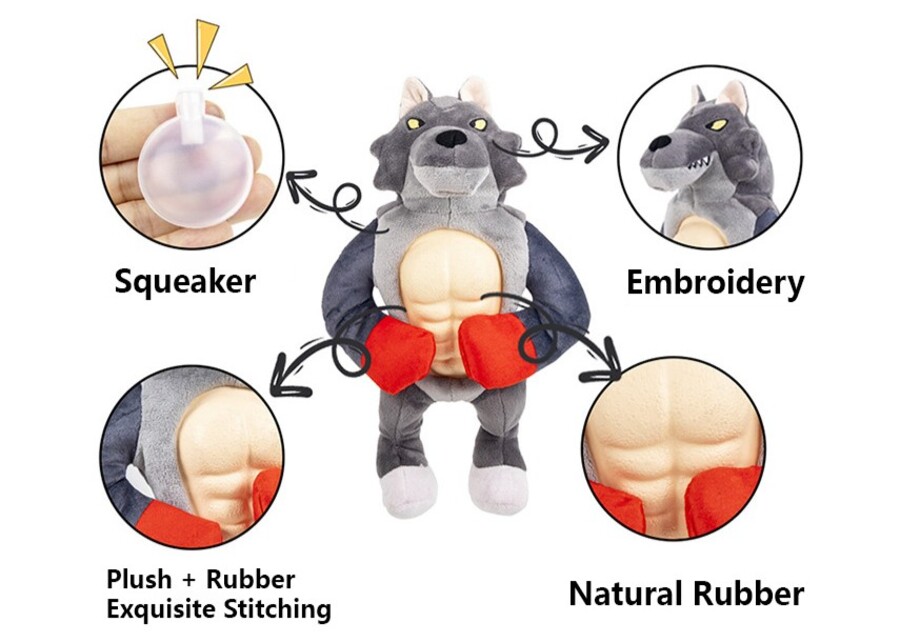

1. Plush & Fabric

These are more than just "soft." We consider fabric weight (GSM) and stitching techniques, like double-stitched seams, to boost durability. We help clients choose the right stuffing—from virgin PP cotton to stuffing-free designs for safety. We also specialize in integrating sensory elements like squeakers and crinkle paper or designing treat-hiding pockets to increase engagement. For your business, plush offers huge branding potential, as it’s easily shaped into unique characters or IP.

2. Natural Rubber

This is the gold standard for durable chew and treat-dispensing toys. We use a process called vulcanization to control the rubber’s hardness and elasticity, tailoring it for gentle puppies or aggressive chewers. This material allows you to build an "eco-friendly" or "all-natural" brand story, which supports a higher retail price.

3. Nylon

We must distinguish between solid nylon and nylon fabric. Solid nylon is an engineering plastic we use for ultra-durable toys for extreme chewers. Through injection molding, we can infuse food-grade flavors like bacon or chicken directly into the material for lasting appeal. This material is perfect for brands that want to build a reputation for "indestructible" toys.

4. TPR (Thermoplastic Rubber)

We call TPR the "versatile star" because it combines the easy processing of plastic with the flexibility of rubber. It’s cost-effective, floats, is durable, and easy to customize with vibrant colors. We only use food-grade, BPA-free TPR. It’s an ideal choice for many OEM/ODM projects as it allows for innovative designs with moderate mold costs.

5. Cotton Rope & Other Textiles

The details matter here. The twist and number of strands in a cotton rope determine its durability and effectiveness as a dental cleaning tool. We always use pet-safe, non-toxic dyes. For your business, rope toys are excellent, low-cost additions to round out a product line or increase the value of a bundle.

6. Plastic

We avoid general terms. We use specific plastics like hard ABS for puzzle toy shells and flexible PP for other components. Our non-negotiable standard is that all plastics must be BPA-free. This material is key for creating complex, interactive, or electronic toys.

7. Latex

Latex is softer than rubber and often used for squeaky toys aimed at puppies or gentle players. We are always transparent with our clients about the potential for latex to cause allergic reactions in some dogs and owners. This honesty is crucial for building trust and making informed product decisions.

8. Different Material Collections

This is where our ODM expertise truly shines. We create innovative toys by combining materials. For example, we recently worked with Maria, an Australian dog trainer who wanted a unique "sensory toy." We designed a product with a durable TPR frame for chewing, soft plush sections for comfort, and knotted cotton ropes for tugging. This composite toy gave her a unique, high-value product that stood out in her market.

What factors should I consider when choosing materials?

Feeling pulled in different directions by cost, durability, and branding? Choosing a material without a clear strategy can hurt your bottom line and brand reputation. Let’s create a framework.

Consider five key factors: your target dog’s profile (size, chew style), the toy’s function (chew, fetch, puzzle), your brand’s cost-effectiveness, customization potential, and global compliance needs. Balancing these will lead to a successful product.

Selecting a material isn’t a simple checklist; it’s a strategic business decision. We guide our clients through this process by reframing common questions into a business context. This ensures the final product aligns perfectly with their market goals, brand identity, and financial targets. Here’s how we break it down.

1. Dog’s Breed, Size, and Chewing Style

We translate this into Target Market Segmentation. We ask our clients: "Is your brand for gentle companions in city apartments, or for powerful working dogs on large properties?" A toy for a Chihuahua has vastly different material requirements than one for a German Shepherd. Answering this question first defines the entire project’s technical specifications.

2. Toy Functionality & Play Type

This is about your Product Line Strategy. A successful brand offers a range of solutions. Does your product line need a durable chew toy (nylon, rubber) for quiet time, an interactive fetch toy (TPR, rope) for bonding, or a brain-engaging puzzle toy (plastic, composites)? Each function points to a different ideal material.

3. Cost-Effectiveness for Your Brand

We focus on Return on Investment (ROI), not just the lowest unit price. We transparently discuss how raw material costs, one-time mold fees, manufacturing complexity, and Minimum Order Quantities (MOQ) affect the final price. A $0.80 nylon toy that builds brand loyalty is often more profitable than a $0.30 plush toy that gets destroyed in minutes and leads to bad reviews.

4. Brand Identity & Customization Potential

Your material choice tells a story. If your brand is eco-conscious, natural rubber and recycled fabrics are your voice. If it’s about toughness, engineering nylon speaks volumes. Here, we seamlessly integrate our private label and ODM services, showing how we use material and color to align your product with your brand’s visual identity.

5. Compliance & Global Market Access

This is where our experience becomes your biggest asset. We are experts in the safety standards for major markets like North America (ASTM F963), Europe (EN-71), and Australia. Partnering with us means you avoid costly recalls, customs issues, and legal risks from the very start. We ensure your product is ready for the global stage.

How do I analyze the pros and cons of materials for my business?

Trying to compare materials feels like comparing apples and oranges? Without a clear framework, it’s easy to get lost in technical details and lose sight of the business implications.

Use a structured analysis that weighs each material’s best use case against its business pros and cons. This method provides a clear, side-by-side comparison, making it easier to see which material aligns with your brand’s strategic goals and budget.

To make this decision process easier for our partners, we’ve developed a straightforward framework. It moves beyond simple descriptions and focuses on what each material choice means for your business—from product positioning to manufacturing considerations. This table is a tool we use to help our clients make informed, strategic decisions.

| Material | Best For (Product Type) | Business Pros (Why Choose It) | Business Cons (What to Consider) | Preeminent’s Manufacturing Tip |

|---|---|---|---|---|

| Natural Rubber | Durable Chew Toys, Treat Dispensers | High perceived value, eco-friendly story, supports premium pricing. | Higher raw material cost, heavier weight (shipping cost). | We recommend a durometer (hardness) test to precisely match the rubber density to your target chewer profile. |

| TPR | All-rounders, Floating Toys, Interactive Toys | Excellent cost-performance, highly customizable (color/shape), lightweight. | May not withstand the most extreme chewers compared to solid nylon. | Ideal for co-molding with other materials to create innovative, multi-textured toys at a controlled cost. |

| Nylon (Solid) | Extreme Chew Toys | Ultimate durability, builds a strong brand reputation for "tough" toys. | High initial mold cost, less flexible in design, higher unit price. | We can infuse food-grade flavorants directly into the nylon during the injection process for long-lasting appeal. |

| Plush & Fabric | Cuddle Toys, Light Chew/Indoor Play | High emotional appeal, vast design possibilities (IP friendly), lower cost per unit. | Not durable for chewers, potential for stuffing to be ingested. | We use reinforced stitching and can offer stuffing-free designs to mitigate safety concerns for our clients. |

| Cotton Rope | Tug-of-War, Fetch, Dental Chew Toys | Low cost, classic appeal, provides dental benefits, great as an add-on item. | Can be shredded, not for unsupervised play with heavy chewers. | The tightness of the weave is critical. We adjust the braid density to balance durability with a satisfying chew texture. |

| Plastic (ABS/PP) | Puzzle Toys, Interactive Feeders | Excellent for creating complex mechanisms and innovative functions. | Can become brittle, requires strict quality control to ensure it’s BPA-free. | For puzzle toys, we focus on smooth-molded edges and secure closures to ensure safety and prevent frustration. |

How do I make the right choice for my business?

Worried you’ll invest in a product that doesn’t fit your brand or market? The final decision can feel immense, with your brand’s reputation and capital on the line.

The best choice comes from partnership. By combining your brand vision with our manufacturing expertise, we can select a material that is safe, marketable, and profitable for your business, ensuring alignment with your strategic goals.

Ultimately, our goal is to empower you to make the best possible choice. There is no single "best" material, only the material that is best aligned with your specific business strategy. We see our role as more than a manufacturer; we are your strategic partner in product development. Our extensive experience with our core services—ODM, OEM, and One-Stop Sourcing—is built on this foundational understanding of materials. For example, we worked with David, the owner of a US outdoor gear company. He wanted to extend his brand into the pet space. His customers are avid hikers who take their dogs on adventures. We guided him toward a composite design using durable nylon and natural rubber, creating a line of chew toys shaped like miniature climbing gear. This ODM project was a perfect, authentic extension of his rugged brand. In another case, Sophie, who runs a fast-growing e-commerce store in Europe, needed to quickly broaden her product catalog. She didn’t have time to manage multiple suppliers. She came to us with a list of popular product categories. Leveraging our One-Stop Sourcing service, we procured everything from plush toys to TPR fetch balls, ensured consistent quality across the board, and consolidated the shipment, saving her significant time and money. Whether you have a unique product concept waiting to be born or need a reliable partner to source proven winners, our deep understanding of materials is the cornerstone of your success.

Conclusion

The best dog toy material is not a single answer. It is the one that strategically aligns with your brand, target customer, and business goals. Let’s build it together.

Frequently Asked Questions

What is the most indestructible material for a dog toy?

While no toy is truly indestructible, the closest you can get for extreme chewers is solid, high-quality nylon. Its dense, engineered structure is designed to withstand incredible force. Hard natural rubber is also an excellent choice for powerful chewers. The key is matching the material’s density and design to the target dog.

Are dog toys manufactured in China safe?

Safety is determined by the manufacturer’s standards, not the country of origin. As a China-based manufacturer, we ensure safety by enforcing strict quality controls. This includes sourcing only high-quality, non-toxic raw materials, adhering to international safety standards like ASTM F963 and EN-71, and conducting rigorous inspections before, during, and after production. A reputable partner is your guarantee of safety, regardless of location.

How does material choice affect the cost and MOQ of a custom toy?

Material choice is a primary driver of cost and Minimum Order Quantity (MOQ). Materials like solid nylon or those requiring complex molds often have higher initial setup costs and MOQs to make production viable. Simpler materials like plush or cotton rope generally allow for lower MOQs and unit costs. We work with clients to find the right balance that fits their budget and business goals.

What are the best materials for puppy toys?

For puppies, we recommend softer yet durable materials that are gentle on their developing teeth and gums. Food-grade TPR and Plush is an excellent choice because it’s flexible, durable, and can be textured to soothe teething discomfort. Softer natural rubber and specially designed plush toys with reinforced seams are also great options for young dogs.

Can you combine different materials in a single toy design?

Absolutely. This is one of our key strengths in ODM manufacturing. Combining materials—like a plush body with TPR feet or a nylon bone wrapped in rubber—creates multi-textured, highly engaging toys that stand out in the market. This approach allows your brand to offer unique benefits, such as a toy that is both comforting and durable for chewing.