Great plush dog toys design means nothing if reviews scream "Destroyed in minutes." For brand owners, the culprit isn’t usually stitching—it is the wrong fabric choice.

Fabric selection accounts for 30-50% of your total product cost and is the primary factor in reducing return rates. To balance durability with margins, you must look beyond aesthetics to technical specs like GSM (density), composite backing (lamination), and directional cutting yields. This guide breaks down exactly how we engineer value into every dog plush toy.

Many buyers obsess over softness or extreme durability, missing the balance. Let me show you how we select materials on the factory floor that satisfy both the dog’s instinct and your profit margins.

Why Is Fabric Selection the Most Critical Decision for Your Margins?

Every time a customer returns a shredded toy, you lose the sale, the shipping cost, and the customer’s trust. It is a triple penalty. Most sourcing managers focus on the per-yard price, missing the bigger financial picture.

We practice "Value Engineering" at Preeminent. This means we don’t just sell you a product; we analyze your budget to find the optimal fabric combination. By adjusting the material specs, we can often lower the Return Rate significantly, which protects your brand reputation more effectively than any marketing campaign.

Let me share a story about a client, let’s call him Mark, who runs a mid-sized retail chain in the UK. Mark came to us frustrated. His "Natural Friends" line was getting crushed in online reviews because the toys were tearing at the seams. He thought he had to switch to expensive ballistic nylon to fix it, which would have destroyed his price point.

I sat down with him and explained that the issue wasn’t the material’s cost, but its structure. He was using a single-layer fabric meant for baby toys. In the pet industry, fabric choice is a strategic moat. We shifted his production to a composite fabric. The result? His costs barely moved, but his return rate dropped by 80%.

This is what I mean by Value Engineering. It is not about buying the cheapest cloth; it is about buying the right cloth. If you are targeting the "tough chewer" market, your fabric choices must be radically different from a brand targeting "snuggle companions." We help you align these physical attributes with your commercial goals.

What Is GSM and Why Does It Matter for Dog Toys?

You might see "Crystal Super Soft" listed on a quote, but without the GSM spec, that description is useless. If you don’t know the weight of your fabric, you are flying blind regarding quality control.

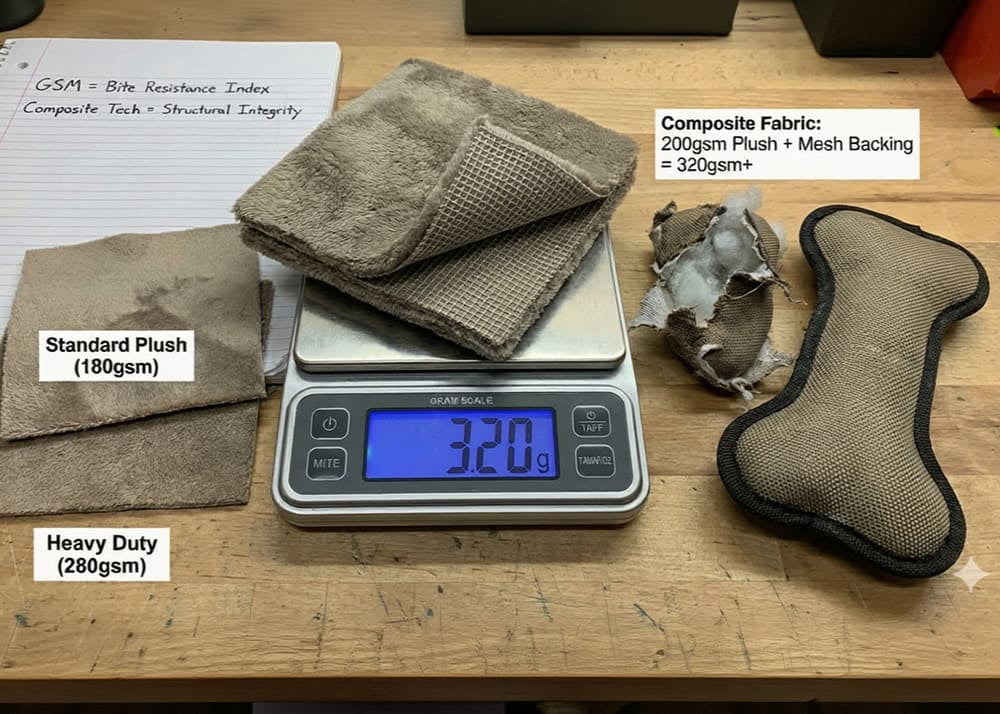

GSM stands for Grams per Square Meter. In the plush toy industry, this is effectively your "Bite Resistance Index." While a standard plush toy might use 180gsm, we rarely recommend anything under 280gsm for dog toys. Higher density means a tighter weave that is harder for teeth to puncture.

Here is a factory secret that many buyers are unaware of: Composite Technology (Lamination/Bonding).

Often, a client will touch a fabric sample and say, "This feels too thin." Instead of sourcing a much more expensive, heavier weave, we use a process called "backing." We take a standard 200gsm aesthetic fabric and laminate a layer of strong mesh or non-woven fabric to the back. Instantly, the fabric weight jumps to 300gsm+, and the tensile strength—the resistance to ripping—doubles.

This is where the difference between baby toys and dog toys becomes critical. Baby toys prioritize extreme softness and safety standards regarding chemical content. Dog toys require what we call "structural integrity." A fabric that is safe for a baby might be destroyed by a Terrier in seconds.

For our B2B clients, I always advise checking the composite specs. Are we using a single layer? Or are we adding a mesh backing? This invisible layer is often the difference between a 4-star product and a 1-star disaster. If you are building a reputable brand, insist on composite reinforcement for any plush body.

Which Fabric Type Suits Your Brand Positioning Best?

Not all plush fabrics are created equal. The material you choose dictates not just durability, but the "personality" of the toy and which marketing claims you can legally and logically make on your packaging.

From high-definition prints to dental-cleaning textures, your fabric choice acts as a canvas for your brand’s story. We categorize materials into main buckets: Entry-level for mass market, Premium for comfort, and Functional for durability and hygiene.

Let’s break down the specific materials we handle daily on our production lines, so you can match them to your product roadmap:

- Crystal Velboa (The All-Rounder): This is the most common fabric for a reason. It has a short pile (fur length), which makes it perfect for Digital Printing. If you are doing an IP collaboration or have a complex character design with tattoos or intricate patterns, this is your best choice. It offers the highest pattern clarity and is cost-effective for "entry-level" product lines.

- Minky / PV Plush (The Premium Touch): This is the "shaggy" soft fur. It feels luxurious to the human hand. We use this for "Comfort & Anxiety Relief" toys. However, be warned: it gets dirty easily.

- Sherpa / Faux Lambswool (The Natural Vibe): This is massive for Fall/Winter collections. It visually signals "organic" and "natural" to the consumer. If your brand ethos is about a "Natural Lifestyle," this is the visual cue customers look for.

- Corduroy (The Dental Marketer): Don’t just list this as "durable." Use it for Functional Marketing. The raised ridges of corduroy texture can help clean a dog’s teeth. We frequently use this for clients who want to add a "Dental Hygiene" claim to their packaging.

- Oxford / Nylon (The Armor): We talk in Denier (D) here—400D, 600D, or Ballistic. This isn’t for cuddling; it’s for armor. We often use this for the "vulnerable" parts of a toy, like ears or tails, to prevent chewing initiation.

- RPET (The Eco-Warrior): This is recycled polyester made from plastic bottles. Crucial Note: In the US and EU markets, without a GRS (Global Recycled Standard) certificate, your eco-claim is just "Greenwashing." At Preeminent, we provide the TC (Transaction Certificate) to prove the supply chain transparency.

Quick Comparison Matrix: Durability vs. Cost

| Fabric Type | Durability Score (1-5) | Cost Efficiency | Best Application |

|---|---|---|---|

| Crystal Velboa | 2/5 | High (Cheapest) | Mass-market, Promo items, IP Collabs |

| Minky/Long Pile | 2/5 | Medium | Premium comfort toys, Sleeping mates |

| Sherpa/Lambswool | 3/5 | Medium | Natural/Organic lines, Seasonal |

| Corduroy | 4/5 | Medium | Dental toys, "Tough" marketing lines |

| Oxford (600D) | 5/5 | High (Performance) | Outdoor toys, Reinforcement patches |

| RPET | Varies | Premium (+15%) | Eco-conscious brand lines |

Factory Insider Bonus: The Hidden Cost of "Yield"

There is a cost factor nobody talks about: Fabric Yield & Cutting Loss.

If you choose a Corduroy or a specific directional print, we must cut all pieces facing the same way so the "grain" aligns. This creates more scrap fabric (waste), increasing your cost per unit. If you choose a non-directional fabric like Crystal Velboa, we can puzzle-piece the patterns tightly, reducing waste. If budget is tight, ask our design team to optimize your pattern for maximum fabric yield.

How Do Printing and Dyeing Processes Affect Perceived Value?

A great fabric can be ruined by poor color application. Nothing kills a repeat purchase faster than a dog with a red-stained mouth because the dye bled the first time the toy got wet.

The choice between Digital Printing and Embroidery is a battle between cost and "Perceived Value." While printing handles complex colors cheaply, embroidery signals luxury. More importantly, safety regarding saliva alkalinity is non-negotiable in our testing protocols.

When we finalize the "look" of the toy, we have to make a technical choice.

Digital Printing is fantastic for small batches (Low MOQ) because there are no expensive screens to make. You can have a design with 20 different colors for the same price as one. However, the pile of the fabric must be short (like Velboa) for the image to be sharp.

Embroidery acts differently. It adds texture and feels expensive. I always advise clients: even if you print the body, embroider your Logo. A printed logo fades; an embroidered logo stays. It elevates the Perceived Value of the item, allowing you to charge a higher retail price.

Finally, we have to talk about chemistry. A dog’s saliva is slightly alkaline. If the Color Fastness of the dye isn’t up to standard (we require Grade 3-4 Wet Rubbing Fastness), the dye will bleed. This is a massive safety concern and a frequent cause of recalls. We strictly control this chemical stability to ensure the toy remains safe even after hours of chewing and drooling.

Conclusion

Fabric choice is brand strategy, not just procurement. Whether you need high-yield Velboa or GRS-certified RPET, Preeminent acts as your technical consultant to engineer value, safety, and durability into every SKU.