Streamlining Pet Supply Distribution: A One-Stop Manufacturing Solution

Key Highlights

Client

Our client operates a thriving pet supply distribution and wholesale business in the United States.

Challenge

A US pet supply distributor faced complex multi-supplier management, inconsistent quality standards, high shipping costs, and inefficient procurement processes, severely impacting business profitability and market competitiveness.

Solution

Through comprehensive one-stop manufacturing and sourcing services, we integrated product development, quality control, logistics optimization, and supply chain management, simplifying complex multi-supplier relationships into a single partnership model, significantly reducing costs and improving operational efficiency.

Results

Client Background & Challenges

Our client operates a thriving pet supply distribution and wholesale business in the United States. As an established distributor, they maintain warehouse facilities in one of the largest wholesale markets in their region. Their business model focuses on supplying local supermarkets and pet retail chains with a comprehensive range of pet products, including toys, bowls, collars, leashes, harnesses, clothing, and beds.

With years of experience in the pet supply distribution industry, our client understood the local market demands and had built strong relationships with retailers throughout their region. However, their success was being hindered by significant operational challenges in their procurement process.

Our client's primary goal was to streamline their procurement operations while maintaining high product quality and competitive pricing. They envisioned a simplified supply chain that would allow them to focus on their core business of distribution and customer relationship management, rather than spending excessive time managing multiple supplier relationships.

The client faced several specific challenges:

- Complex Supplier Management

- Inconsistent Product Quality Standards

- Escalating Logistics Costs

- Inefficient Procurement Processes

Client Objectives

Establish Industry-Leading Product Quality Standards

Achieve 30% Procurement Cost Reduction

Expand Product Line Coverage

Enhance Operational Efficiency and Free Management Focus

Build a Sustainable Supply Chain System

Our Solution

Through comprehensive one-stop manufacturing and sourcing services, we integrated product development, quality control, logistics optimization, and supply chain management, simplifying complex multi-supplier relationships into a single partnership model, significantly reducing costs and improving operational efficiency.

One-stop Sourcing Service Strategy

Key elements of our sourcing strategy included:

- Product Integration and Customization Services

- Unified Quality Control System

- Intelligent Inventory and Procurement Management

- Logistics Optimization and Cost Control

- Full-Service Support and Continuous Optimization

Comprehensive One-Stop Manufacturing Service

We developed a tailored solution that addressed each of the client's pain points through our integrated manufacturing and sourcing platform. Our approach centered on becoming their single point of contact for all pet product needs.

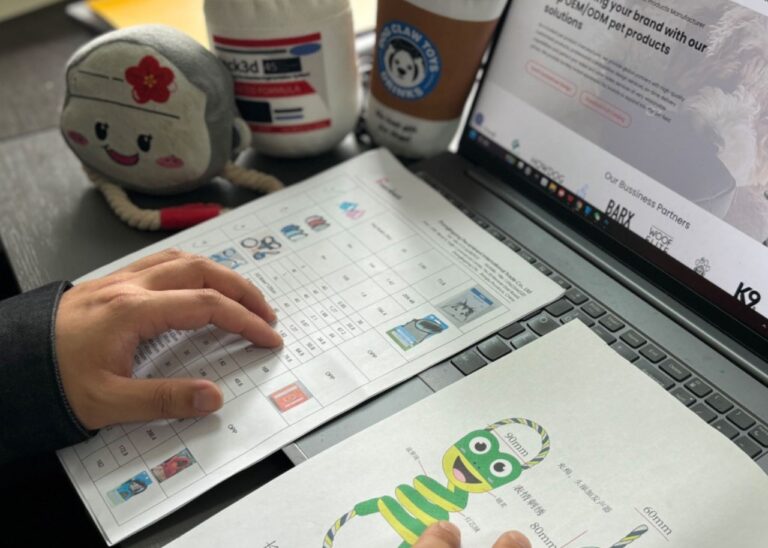

Streamlined Product Selection Process

We streamlined the product selection process by offering two flexible ordering methods: custom product lists based on client specifications and curated catalog selection featuring trending, high-demand pet products.

Integrated Quality Management System

We established an integrated quality management system with rigorous protocols including pre-production sample approval, in-line production checks, final inspection, and complete quality documentation to ensure consistent product standards across all categories.

Implementation Process

Phase 1: Partnership Establishment and Assessment

We began by conducting a comprehensive analysis of the client's existing product portfolio and procurement patterns. This assessment helped us understand their seasonal demands, best-selling products, and quality requirements.

Phase 2: Supplier Network Integration

Leveraging our established relationships with verified pet product manufacturers, we created a curated network of suppliers specializing in different product categories while maintaining consistent quality standards.

Phase 3: Quality Protocol Implementation

We developed customized quality control procedures specific to the client's market requirements and retail partner expectations. This included establishing clear quality benchmarks and inspection criteria for each product category.

Phase 4: Logistics Optimization

Our logistics team redesigned the shipping process to maximize container utilization and minimize transportation costs while ensuring timely delivery schedules that aligned with the client's inventory needs.

Phase 5: Ongoing Relationship Management

We established regular communication protocols and performance monitoring systems to ensure continuous improvement and adaptation to changing market demands.

Results & Benefits

Client Feedback

"Working with this manufacturing partner has completely transformed our business operations. Before partnering with them, we were drowning in supplier management complexity and unpredictable quality issues. Now, we've reduced our procurement costs by 35% while dramatically improving product consistency. Our retail partners have noticed the quality improvement, and we've been able to focus on growing our business instead of managing supplier headaches. This partnership has been a game-changer for our company's profitability and growth trajectory."

— Judy

Insights & Learnings

Key Success Factors

Single Point of Contact

Consolidating multiple supplier relationships into one partnership eliminated communication complexity and reduced management overhead by 60%.

Rigorous Quality Standardization

Implementing consistent quality control protocols across all product categories achieved a 98% quality acceptance rate and reduced customer complaints by 85%.

Logistics Consolidation

Combining multiple product shipments into unified containers reduced transportation costs by 40% and improved delivery predictability.

Flexible Ordering Systems

Offering both custom specifications and curated catalog options streamlined the procurement process and reduced ordering time by 70%.

Continuous Market Adaptation

Regular business reviews and trend analysis enabled rapid response to market changes and sustained competitive advantage in the pet supply industry.

Industry Insights

This partnership demonstrated that complex procurement challenges often require simple, integrated solutions. By consolidating multiple supplier relationships into a single partnership, we eliminated numerous inefficiencies that were draining our client's resources.

The dramatic improvement in product quality consistency not only reduced immediate costs but also strengthened our client's relationships with their retail partners, creating long-term business value beyond the immediate cost savings.

The transportation cost reductions achieved through our consolidation approach created compounding benefits. Lower shipping costs improved profit margins, which enabled competitive pricing that drove increased sales volume.

Streamlining communications from multiple supplier relationships to a single point of contact freed up significant management time that could be redirected toward business development and customer relationship building.

Applicability to Other Projects

This case study illustrates how the right manufacturing partner can transform operational challenges into competitive advantages. By addressing procurement complexity through integrated solutions, we enabled our client to focus on what they do best – building relationships and growing their distribution business.

This case study demonstrates our commitment to solving complex procurement challenges through innovative, integrated manufacturing solutions. If you're facing similar challenges in your pet product supply chain, we'd welcome the opportunity to discuss how our one-stop manufacturing approach could benefit your business.

Product Showcase

Client Testimonials

What our partners say about their experience working with Preeminent

"The one-stop procurement solution exceeded all our expectations. What used to take weeks of coordination with multiple suppliers now happens seamlessly through a single point of contact. The consolidated shipping alone saved us over $50,000 in transportation costs last year. But beyond the cost savings, the reliability and quality consistency have allowed us to expand our product offerings and strengthen relationships with our retail customers. I wish we had found this partnership years ago!"

Kevin

Long-term One-stop Procurement Service Partner

Ready to Develop Your Custom Pet Products?

Let's discuss how we can create tailored pet supply solutions for your brand, just like we did in this case study.