There is nothing worse for a brand owner than receiving a batch of returns because the dog plush toys fell apart in five minutes. You watch your profit margin vanish, not because the design was bad, but because the insides couldn’t handle the playtime.

The internal materials of a plush toy—the stuffing and the noise makers—are the silent factors that determine durability, safety, and return rates. As manufacturers, we help you choose the right "guts" to balance your costs with the performance your customers expect.

We often see clients spend months perfecting the outer fabric pattern but completely ignore what goes inside. This is a mistake. The inside is where the real engineering happens.

In my years running the production line here at Preeminent, I have learned that the lifespan of a plush dog toy is decided before the first stitch is sewn. It is decided when we pick the density of the cotton or the type of squeaker. A beautiful toy that goes flat in an hour gets a bad review. A toy that keeps its shape and sound for months gets you a repeat customer.

As a plush dog toys manufacturer, my role isn’t just to take your order. It is to be your consultant. If you are targeting a high-end boutique market in New York or London, I am not going to let you use low-grade fill that clumps up; I will push you toward high-elasticity materials. If you are selling high-volume to a discount chain, we will adjust the internal specs to hit your price target without compromising basic safety. We look at the "Return Rate" as a key manufacturing metric. Better guts mean fewer returns. It is that simple.

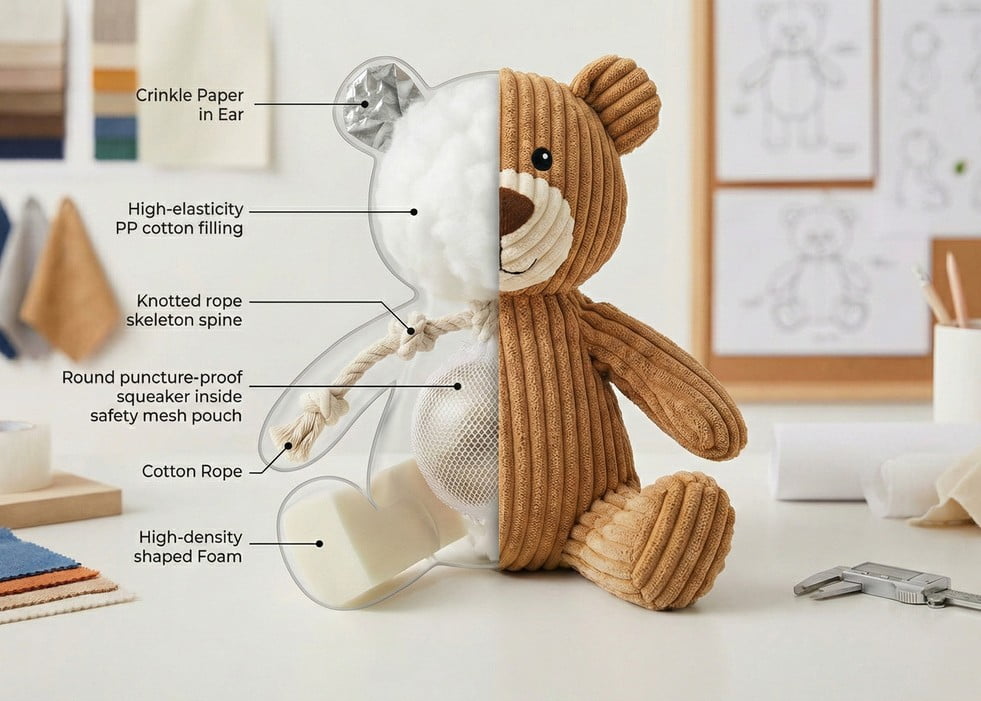

Let me walk you through exactly what we put inside these toys on the factory floor.

Stuffing Options: Beyond Just "Soft"

Softness is subjective, but density and resilience are technical specifications that we can measure and control.

From standard cotton to structural rope skeletons, the choice of filling transforms a toy from a simple pillow into a functional tool for play. Understanding these options helps you create products with specific selling points like "eco-friendly" or "extra durable."

When we plan the production for a new SKU, we look at the function first. Here is how we break down the stuffing options on the factory floor to match your specific market needs:

1. PP Cotton (The Standard Base)

This is your bread and butter. It provides that classic plush feel. However, we don’t just use generic "cotton." For premium orders, we use High-Elasticity PP Cotton. It stays fluffy longer and doesn’t turn into a hard lump after the dog drools on it. Recently, more clients are asking for GRS Certified Recycled Cotton. I had a client from the Netherlands who built his entire brand marketing around sustainability. We switched his entire line to recycled fill. It didn’t change the feel of the toy, but it allowed him to put a "Made from Recycled Plastic" badge on his packaging, which was a huge selling point in the European market.

2. Rope Skeleton (The Internal Spine)

This is a favorite for durability. We embed a knotted rope structure inside the plush body. Think of it as the toy’s spine. It satisfies the dog’s urge to tug and chew. Technically, this reduces the amount of loose cotton we need to use, which lowers the risk of a dog swallowing filler if they tear it open. It makes the toy tougher without making it heavy, perfect for "Tough Toy" marketing lines.

3. Crinkle Paper (The Sensory Instigator)

This is the most cost-effective way to add value. We sew sheets of this noisy plastic into ears, tails, or wings. It triggers a dog’s hunting instinct because it sounds like rustling leaves or small prey. It adds zero weight but massive sensory appeal. It turns a static toy into something that reacts when touched.

4. High-Density Foam (The Shape Keeper)

If you are designing a toy shaped like a camera, a toaster, or a blocky robot, cotton won’t hold those sharp corners. We use high-density sponge or foam. It gives the toy a "Premium Look"—it stands up straight on the shelf and doesn’t look floppy. It also offers a different mouthfeel; it’s dense and satisfying to bite down on, bouncing back instantly.

5. Functional Hybrid Core (The Upgrade)

This is for the "Destroyers." We call this the "Surprise Inside" or 2-in-1 design. We hide a durable TPR (Thermoplastic Rubber) spike ball or a rubber bone inside the plush. When the dog inevitably rips the fabric, they find a second toy inside. It turns a negative moment (breaking the toy) into a positive one (new toy!). We also use EVA or ETPU cores for amphibious toys. These materials are light and float, so even a plush toy can be used for fetch in the pool.

6. The "Stuffing-Free" Option (The Clean Choice)

Some owners hate cleaning up white fluff. For them, we make "flat" toys. But we don’t just sew two pieces of thin cloth together. We use a Laminated Fabric process. We bond a layer of mesh or fleece to the outer fabric to give it thickness and durability without any loose stuffing. It is the cleanest option for indoor play and very popular among urban pet owners.

Squeaker Options

A silent toy is often a boring toy, but the type of sound must match the size of the dog and the patience of the owner.

The squeaker is the soul of the toy, driving interaction and engagement. We offer everything from self-healing puncture-proof units to low-tone grunters, ensuring the sound matches the intended play style and user experience.

The squeaker isn’t just an accessory; it dictates how the dog plays. As a manufacturer, we categorize them by interaction style:

- Standard Squeakers: The classic round "BB" sound. These are cheap, effective, and good for entry-level items. They are the industry standard for a reason, but they don’t offer much differentiation.

- Puncture-Proof Squeakers: This is a major upsell feature. These squeakers have a self-sealing mechanism. Even if a dog’s tooth punctures the plastic bladder, it still squeaks. If you market your toys as "Indestructible" or "Tough," you need this component. It prevents the toy from becoming "dead" after one rough play session, which significantly reduces negative reviews.

- Deep Tone Grunters: We use these for larger toys. Instead of a high-pitched squeak, it makes a low grunt (like a pig). I often recommend this for large dog toys. Big dogs seem to respond better to deeper sounds, and frankly, the human owners prefer it because it is less annoying than a high-pitched whistle.

- Crackle / Giggler Tubes: These don’t need to be bitten. They make a "giggling" sound when shaken. We put these in long, stick-shaped toys or animals with long necks. It encourages shaking and thrashing play rather than just chewing.

Safety Installation: The Mesh Pouch Upgrade

Standard procedure is to bury the squeaker deep in the cotton. But for clients with strict safety requirements (especially those selling in strict markets like Germany or the USA), we offer a Premium Upgrade. We wrap the squeaker in a reinforced nylon mesh bag before sewing it into the toy. This acts as a secondary barrier. If the dog rips the outer skin, the squeaker is still trapped in the mesh, preventing a choking hazard. It costs a few cents more, but it is a powerful "Safety First" marketing claim you can print on your box.

Quality Control

We can use the best materials in the world, but if a needle is left inside a toy, it is a disaster for your brand and my factory.

Quality control is the non-negotiable final step that ensures every product is safe for pets and children. From metal detection to pull tests, we implement rigorous checks to protect your reputation and meet international safety standards.

In B2B manufacturing, trust is built on consistency. You need to know that the 1,000th toy is as safe as the 1st. Here is how we ensure that "invisible safety net" at Preeminent.

Metal Detection (The 100% Rule)

Every single plush toy that leaves our production line goes through a tunnel metal detector. No exceptions. Sewing involves needles, and sometimes needles break. It is a reality of manufacturing. Our detectors are sensitive enough to find a 1mm piece of broken metal buried deep in the stuffing. If the machine beeps, that toy is isolated and surgically opened to find the fragment. We never ship a toy that hasn’t passed this check. This is standard for us, but you should always verify your supplier does this.

Pull Tests (The Strength Check)

We don’t just look at the toys; we stress-test them. We have a dedicated testing lab where we perform tension tests on the "small parts"—the plastic eyes, noses, and any attached accessories. We clamp the toy and pull the eye with a specific force (according to ASTM F963 or EN71 standards) to make sure it doesn’t pop off. Loose eyes are choking hazards.

I remember a new client who wanted to use a very specific, cute button nose for a teddy bear design. It looked great visually, but it failed our pull test every time because the backing washer was too small. We refused to produce it until we sourced a reinforced washer that locked it in place. We might have delayed production by three days, but we saved them from a potential recall. That is the kind of partnership we offer. We protect your brand by being strict with our own production.

Conclusion

There is no "best" material, only the right material for your specific price point and target dog. Whether you need eco-friendly recycled cotton, puncture-proof durability, or a low-cost promotional item, we can customize the "guts" to fit your business goals.

Would you like to feel the difference yourself? Contact us today to request a Sample Kit containing our different stuffing and squeaker options.