You’re tired of customer complaints about “indestructible” toys that get shredded in minutes. This hurts your brand. We’ll show you how truly durable toys are engineered, from concept to container.

Truly durable dog toys are not just made from strong materials. They are the result of a complete system that combines material science, intelligent structural design, and obsessive quality control. This system ensures a toy is both tough and safe for aggressive chewers, protecting your brand’s reputation.

You’ve probably seen countless toys labeled "tough" or "indestructible," only to see them fail. Why does this happen? Because true, reliable durability isn’t about a single feature. It’s a complex engineering process that starts at the molecular level of the material and continues all the way through the production line. In this article, we’re going to pull back the curtain and show you exactly how it’s done. It’s important to remember that every dog is different—their breed, jaw strength, and chewing style all play a role. Our goal is to engineer toys that can stand up to the widest possible range of powerful chewers, giving your customers the best possible experience.

Why Durability is Critical for Your Pet Brand’s Reputation?

Worried about the damage from negative reviews? A single failed toy can quickly create a wave of bad press and customer distrust. We help you build a brand that stands for quality.

Every durable toy you sell is a long-term investment in your brand’s reputation, generating positive reviews and repeat customers. In contrast, a flimsy toy becomes a direct liability on your balance sheet, costing you sales, trust, and credibility.

Think of your brand as having a financial balance sheet. Every product you sell either adds to your assets or your liabilities. A toy that breaks prematurely is a clear liability. It leads to customer service costs, refunds, and worst of all, negative online reviews that live forever. Each one-star review chips away at the trust you’ve worked so hard to build.

On the other hand, a genuinely durable toy is one of your most powerful assets. It doesn’t just result in a single happy customer. That customer leaves a five-star review. They tell their friends at the dog park. They come back to buy more products from your brand because they trust your quality. This positive word-of-mouth generates compound interest for your brand, building a loyal following that competitors can’t easily steal. At Preeminent, we don’t just see ourselves as making toys; we see ourselves as helping you manage business risk and build long-term brand equity.

What Materials Can Withstand a Power Chewer’s Jaw?

Confused by all the material options out there? Choosing the wrong one leads directly to broken toys and unsatisfied customers. We make the science simple so you can make a smart choice.

The best materials for power chewers range from industrial-grade rubber and nylon to specially engineered fabrics for plush toys. The key is matching the material and construction to the dog’s play style, balancing extreme durability with safety and texture.

There is no magic, one-size-fits-all material. The real secret is understanding the trade-offs. But what about plush toys? Can a soft toy ever be truly durable? This is where engineering shifts from pure material science to advanced construction. A "durable" plush toy isn’t meant to be an indestructible chew block like nylon. Instead, it’s designed with reinforced seams and tear-resistant fabrics to withstand intense games of tug-of-war and vigorous shaking.

Our role as your manufacturing partner is to act as your consultant. We guide you to the best material and design combination for your brand’s specific goals. Here’s a quick breakdown to help you think like an expert:

| Material | Key Advantage | Main Consideration | Best For |

|---|---|---|---|

| Natural Rubber | Excellent toughness & bounce | Higher cost, requires quality sourcing | All-around chew toys, fetch toys |

| Nylon | Extreme hardness & durability | Can be too hard for some dogs | Long-lasting chew toys, dental toys |

| TPE | Highly versatile, variable hardness | Performance depends on formulation | Puzzle toys, toys needing flexibility |

| Reinforced Fabrics | Soft texture dogs love | Durability comes from construction (e.g., multi-layer fabric, reinforced stitching), not for unattended chewing. | Supervised heavy play, tugging, shaking. |

Whether it’s a rubber compound, a nylon polymer, or a high-grade textile, we insist on sourcing only virgin materials from our trusted suppliers. We know firsthand how a single bad batch of raw material can destroy a product line and damage a brand’s reputation. That is a risk we will never take with your products.

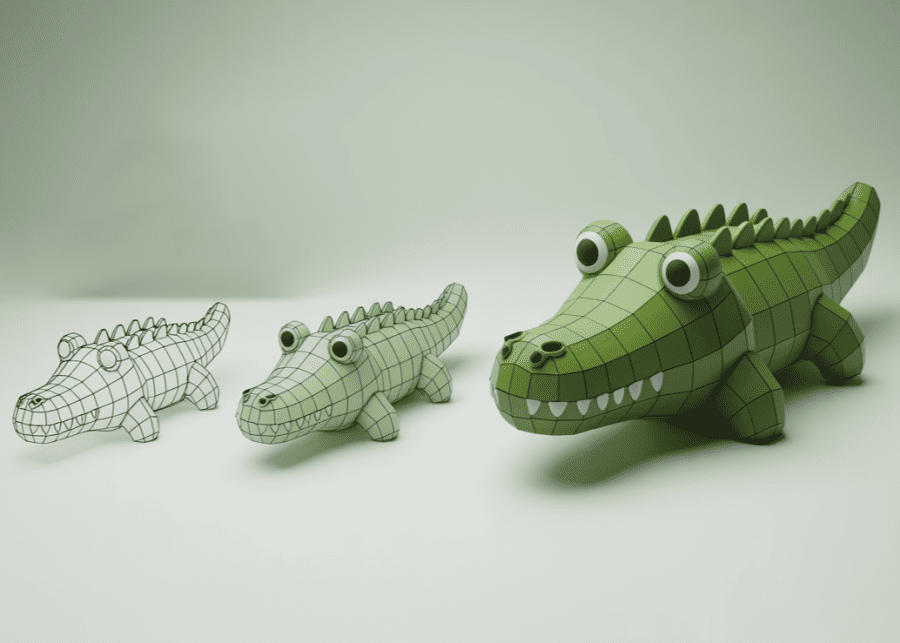

How Structural Design Dictates a Toy’s Lifespan?

Have you ever wondered why some toy shapes break so easily? It’s not just bad luck; it’s almost always a failure of design. We approach toy making like architects building a bridge or engineers reinforcing a structure.

A toy’s lifespan is determined by its structural integrity, not just its material. For both hard toys and plush toys, smart design eliminates weak points like corners, thin walls, and especially seams, where dogs instinctively focus their powerful bite force.

Imagine a dog’s jaw as a powerful lever. Any weak point on a toy becomes a perfect place for the dog to apply maximum force. This is where most toys fail. The challenge is to create an interesting shape for the dog that has no obvious structural weaknesses. Our ODM team thinks like structural engineers, but the approach changes depending on the toy.

For Molded Rubber & Nylon Toys:

We use a thought process similar to Finite Element Analysis (FEA) to predict where a dog is most likely to attack. We then design out these weaknesses:

- Unibody Molding: We favor single-piece molding to eliminate seams, which are the most common failure point in poorly made hard toys.

- Rounded Corners: Sharp corners create stress points. We use smooth, rounded corners to spread bite forces across a wider surface area.

- Optimized Wall Thickness: We ensure the toy has a consistent, substantial wall thickness, leaving no thin spots for a dog’s tooth to puncture.

For Durable Plush Toys:

The engineering is different, but the goal is the same: eliminate weak points.

- Reinforced Seams: This is the most critical element. We use multiple rows of stitching, heavy-duty thread, and often add a layer of reinforcing nylon tape inside the seams to prevent them from being ripped apart during intense tugging.

- Multi-Layer Fabrics: The toughest plush toys feature multiple layers of material bonded together, creating a shell that is much more resistant to tearing and punctures.

- Strategic Construction: We minimize appendages like ears or tails that are easy to target. When they are part of the design, they are attached with reinforced stitching deep into the main body of the toy.

This is the art and science of design. It’s how our engineering, whether in a steel mold or at an industrial sewing machine, transforms high-quality materials into a truly durable toy that protects your brand.

Are These Power-Chewing Materials Actually Pet-Safe?

You might worry that a material strong enough to be "durable" might also be "toxic." This is a valid and critical concern for any responsible brand owner. We believe safety is not negotiable.

Yes, the most durable materials can and absolutely must be pet-safe. We build safety into our process with a “dual insurance” system: first, we source only pure, non-toxic raw materials, and second, we rigorously test the final products to ensure they meet the highest international safety standards.

A common industry misconception is that durability and safety are opposites. The truth is, a non-safe durable toy is far more dangerous than a flimsy one. The risks of chemical leaching from low-grade materials or a dog swallowing a large, hard chunk that breaks off are significant. These are risks that can lead to catastrophic harm for a pet and your brand.

That’s why our safety philosophy is built on a non-negotiable, two-layer approach.

- Source Control: We don’t just buy materials on the open market. We have a demanding qualification process for our raw material suppliers. We require documentation and certificates of analysis for every single batch to ensure it is free from lead, heavy metals, phthalates, and other harmful substances. The purity of the material at its source is our first line of defense.

- Finished Product Testing: After the toy is made, we conduct further testing. Based on your target market, we ensure products comply with the highest standards, such as FDA regulations in the US or REACH standards in Europe. Safety is our unbreakable promise to you and your customers.

What Quality Control Steps Ensure a Toy is Safe & Indestructible?

How can you be sure about product quality when your factory is thousands of miles away? We solve this problem by making our quality control process completely transparent to you.

Our quality control is a multi-stage “boot camp” that every toy must pass. It includes machine stress testing for strength, detailed manual inspection for any physical defects, and final verification of your order before it ships. We provide detailed reports and photos so you can have complete confidence.

Before any product leaves our facility, it goes through a series of rigorous checks. We want you to feel like you are right here in the workshop with us.

- The ‘Devil’s Training Camp’: We use specialized machinery to test the limits of our products. A tension testing machine pulls the toy to measure its breaking point. A compression machine simulates thousands of powerful, repetitive bites to test its long-term resilience against chewing fatigue.

- The Expert Eye: Our trained QC inspectors then examine each toy by hand. They are looking for the tiny imperfections that machines might miss—a small, sharp piece of molding flash, an inconsistency in the color, or any surface blemish. They are trained to be your most demanding customer.

- Pre-Shipment Verification: Trust is built on transparency. For every order, we provide you with a complete set of photos: detailed pictures of your finished products, photos of the packaging and cartons, and even pictures of your container being loaded. You will have a complete visual record and total peace of mind before your shipment ever leaves our port.

OEM vs. ODM vs. Private Label: What’s Best for Your Business?

OEM, ODM, Private Label—all the industry jargon can be confusing. Don’t worry about the definitions. Let’s talk about your business goal, and we’ll show you the right path.

The best manufacturing approach depends entirely on your business strategy. ODM is for creating a totally unique product. OEM is for producing your existing design. Private Label is the fastest way to add proven best-sellers to your product line.

Theory is boring, so let’s look at two common client scenarios.

-

The Innovator (Needs ODM): Think of a client like Kevin from the USA. He owns a successful craft beer brewery and saw an opportunity to connect with his customers, many of whom are dog lovers. He came to us with a brilliant and unique idea: create a plush dog toy that looks exactly like his best-selling beer bottle. He had the brand concept but needed our expertise to turn it into a safe, durable, and appealing toy. For him, our ODM (Original Design Manufacturing) service was the perfect fit. We took his unique idea from a concept to a mass-produced reality, handling the design, material selection, and safety engineering. This helped him launch a highly successful new merchandise category for his brand.

-

The Retailer (Needs Private Label & One-Stop Sourcing): Now, think of a client like Judy, who owns a chain of pet stores. She needs to stock her shelves with a wide range of high-quality, market-tested products without the long development time. For her, our Private Label service is the ideal solution. She can select from our catalog of proven best-sellers—from toys to bowls to beds—and we put her brand and packaging on them. Our one-stop sourcing consolidates everything into one shipment, saving her massive amounts of time and money.

Your business goal determines our method of cooperation. We’re here to be a flexible partner that adapts to your specific needs.

How to Partner with Us to Create Your Own Chew Toy Line?

Ready to launch your own line of durable dog toys but worried it will be a complicated process? We have spent years making it simple, clear, and efficient for our partners.

Partnering with us is a straightforward, three-step journey. It starts with a conversation about your idea, moves to design and sampling until you are 100% happy, and ends with our team managing all production, quality control, and global delivery for you.

Creating a private label product line might sound daunting, but with Pre-eminent, it’s a managed and transparent process. We’ve broken it down into three simple stages to take your idea from a dream to a reality sitting in your warehouse.

Step 1: The Conversation (Your Idea + Our Expertise)

It all begins with a simple email to us. You bring your vision, your brand goals, and your questions. We bring over a decade of specialized experience in design, materials, and manufacturing. We’ll work together to define the product, target cost, and best path forward.

Step 2: The Blueprint (Design, Prototyping & Your Approval)

Our team gets to work, creating technical drawings and, most importantly, a physical sample. There’s no substitute for seeing and feeling the product yourself. You get to test it and provide feedback. We will refine the sample until you approve it with 100% confidence.

Step 3: The Delivery (Production, QC & Logistics)

Once you approve the final sample, you can relax. Our team takes over from here. We manage the mass production, implement our strict quality control process at every stage, and handle all the logistics to deliver your products efficiently and cost-effectively.

Your brand’s next best-seller is just one conversation away. Are you ready to take the first step?

Conclusion

Creating a genuinely durable dog toy is a science. It combines expert material selection, smart engineering, and uncompromising quality control. We are here to be your trusted partner in that process.