Launching a plush toy line feels exciting, but the manufacturing process is full of hidden risks. A wrong move can hurt your brand and your bottom line.

As a pet brand entering the plush toy market, you need a clear roadmap. This involves understanding safety compliance, balancing cost with quality, and knowing how to transform a creative idea into a profitable, bestselling product. This guide provides the answers you need for success.

This guide is built from our 10+ years of experience helping brands just like yours navigate the entire manufacturing journey. We’ve seen what works, what doesn’t, and what separates a one-hit-wonder from a long-term bestseller. We want to share that knowledge with you. We’ll walk you through everything from the initial spark of an idea to getting your final product onto the shelf, ensuring you feel confident and in control every step of the way. Let’s begin by exploring why plush toys are such a powerful tool for your brand.

Why Are Plush Toys a Must-Have for Pet Brands?

Your products are useful, but do they create a real connection? Without an emotional bond, you are just another option on the shelf, easily replaced by a competitor.

Plush toys are a must-have because they build a deep, emotional connection. A food bowl is a tool, but a plush toy is a companion. This unique role turns your brand into a trusted, beloved part of the family, creating powerful and lasting loyalty.

When we talk about brand building, we often think about logos, colors, and marketing messages. But the real connection happens in the customer’s home. Think about it: your logo on a food bowl is seen at mealtimes. Your branding on a leash is visible during walks. These are functional touchpoints. A plush toy, however, is different. It’s carried from the living room to the bedroom. It’s there for a game of fetch in the yard and for comfort during a thunderstorm. It becomes part of the family’s daily life.

From Utility to Emotional Asset

Your brand is no longer just a provider of goods. It becomes a source of joy and comfort. This is the difference between a product and an emotional asset.

- Constant Presence: The toy is a constant, positive reminder of your brand, integrated into the pet’s and owner’s lives.

- Building Trust: When a pet loves and trusts a toy, that positive feeling extends to the brand that made it.

- Brand Loyalty: This emotional bond is incredibly difficult for competitors to break. Customers become loyal not just because of quality, but because of the shared experience your brand has provided. Your logo, stitched onto a soft toy, becomes a symbol of a happy pet.

Toy Safety: How to Choose Compliant Materials?

A product recall is one of the biggest fears for any brand owner. A single safety issue can destroy years of hard work and customer trust in an instant.

Choosing compliant materials is fundamentally about risk management for your brand. This means selecting non-toxic fabrics, safe fillings, and durable components that meet global standards like ASTM F963 or EN71. This protects pets and safeguards your brand’s reputation.

We view ourselves as your brand’s chief safety officer. Our job is to help you build a safety firewall around your products. This isn’t just about passing a test; it’s about protecting the pets who use your products and the brand you’ve worked so hard to build. This firewall is constructed from several critical layers of material and construction choices.

Building Your Brand’s Safety Firewall

| Safety Layer | Key Considerations | Why It Matters |

|---|---|---|

| Outer Fabric | Must be non-toxic and colorfast. Common safe choices include crystal velvet and canvas. | This is the primary point of contact. The material must not contain harmful dyes or chemicals that could be ingested. |

| Inner Filling | Use 100% new, non-toxic PP cotton. Avoid recycled materials with unknown origins. | Dogs will inevitably tear toys open. The filling must be safe if accidentally swallowed and free from contaminants. |

| Stitching & Seams | High-tensile strength thread, with double-stitching on key stress points. | This is the first line of defense against the toy breaking apart and creating choking hazards from small pieces or stuffing. |

| Add-on Components | Avoid small, hard plastic parts (like eyes or noses). Opt for embroidery instead. | Hard components can easily be chewed off and swallowed, posing a serious choking or internal blockage risk. |

Every one of these details works together to ensure your product is not just fun, but fundamentally safe.

How to Create a Bestseller Plush Toy from Scratch?

You have a brilliant, unique idea for a toy. But how do you turn that vision into a physical product that people will actually buy, without losing the magic along the way?

To create a bestseller, you need a manufacturing partner who acts as a co-creator, understanding both your brand and the market. The process involves translating your concept into a viable design, selecting materials for feel and function, and perfecting a prototype that captures your vision.

We believe the best products come from true collaboration. We’re not just a factory that takes orders; we’re a partner that helps bring your vision to life. The perfect example of this is our work with Garrett, a US-based brand owner.

Case Study: A "Co-Creator" Journey

Garrett owns a successful brand of pickleball paddles. He noticed that many players brought their dogs to matches, and the dogs were often bored. He came to us with a unique idea: could we create a plush dog toy that looked exactly like his bestselling pickleball paddle?

- Understanding the Vision: Garrett didn’t just want a toy. He wanted a brand extension1. He wanted to engage the pet-owning part of his audience and create a new revenue stream built on his existing brand recognition.

- The Design Challenge: Our design team got to work. We had to capture the look of his paddle perfectly while making it completely dog-safe. This meant no hard edges, using durable fabrics that could withstand chewing, and adding squeakers for engagement.

- From Concept to Reality: We worked closely with Garrett through every step. We provided design mockups, sent material swatches, and created prototypes. He was able to see and feel the product as it developed.

- The Bestseller: The final product was a huge success. It was a fun, durable toy for dogs and a clever, "insider" product for the pickleball community. It strengthened his brand and opened up an entirely new market. This is what we mean by being a co-creator.

The ODM Journey: From Design Draft to Final Product?

Handing your product idea over to a manufacturer can feel like a loss of control. You worry that the final product won’t match your vision, leading to costly mistakes and delays.

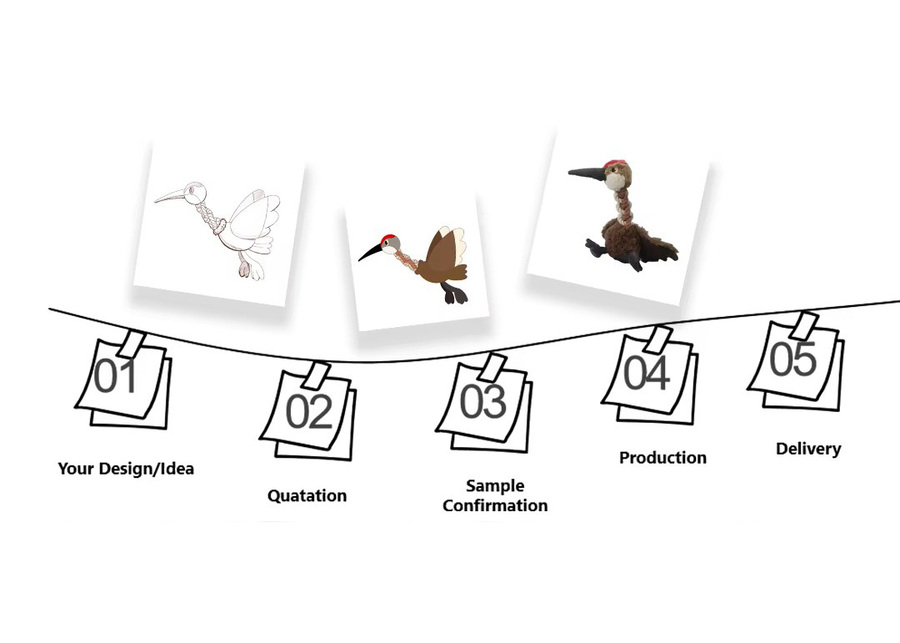

The ODM journey is a transparent, step-by-step process designed to keep you in full control. From the initial design to the final pre-production sample, your approval is required at every key stage. You are always the final decision-maker.

We’ve structured our Original Design Manufacturing (ODM) process to be completely transparent, making you the central architect of your product. You will never be in the dark about what’s happening. Think of us as your expert execution team, and you are the project director with the final say. The journey is clear and predictable, ensuring there are no surprises.

Your Milestones for Approval

- Concept and Design Finalization: We start with your idea, sketches, or inspiration. Our team works with you to create a formal design draft, specifying dimensions, features, and materials. You approve this draft before anything is physically made.

- Material and Color Swatching: We send you physical samples of the proposed fabrics, threads, and other materials. You can feel the quality and see the exact colors. You approve all materials before we create the first sample.

- First Sample (Prototype) Review: We create the first physical prototype based on your approved design and materials. We ship this to you for review. You can check the feel, size, and overall quality. You provide feedback for revisions or approve the prototype to move forward.

- Pre-Production (Golden) Sample Approval: After any revisions, we create a final pre-production sample. This "golden sample" is the exact standard that every single unit in mass production will be held to. You give the final green light on this sample before we start the full production run.

What is the Plush Toy Production Process?

Once you approve the final sample, what actually happens inside the factory? You can’t be on the factory floor, so you might worry about whether quality standards are being maintained.

The production process is a precise, multi-stage system. It starts with laser-guided cutting, moves to detailed embroidery, then high-strength stitching, consistent stuffing, and final assembly. Every toy then undergoes a final quality and safety check before packaging.

We want you to feel as if you are right here with us, watching your product come to life. Let’s walk through the key stages. This isn’t just random assembly; it’s a carefully choreographed process designed for quality, consistency, and safety. We’ve invested in both technology and skilled craftspeople to ensure every single toy meets the standard set by your approved "golden sample."

A Look Inside the Factory

- Stage 1: Precision Cutting: We don’t use hand scissors for the main shapes. Computer-guided laser cutters read the digital patterns to cut multiple layers of fabric at once. This ensures every single piece is identical, with clean edges, which is critical for consistent sizing and strong seams.

- Stage 2: Embroidery & Detail Work: Before the toy is sewn together, individual fabric pieces are sent for branding. Your logo is embroidered with high precision for a clean, professional look that won’t peel or fade.

- Stage 3: High-Strength Stitching: Our skilled workers use industrial sewing machines with high-tensile nylon thread. We pay special attention to stress points like necks and limbs, often using double-stitching to withstand enthusiastic play and pulling.

- Stage 4: Consistent Stuffing & Squeaker Placement: Each toy is filled with new, clean PP cotton. To ensure a uniform feel and shape across the entire batch, each toy is weighed during the stuffing process. Squeakers are securely placed inside.

- Stage 5: Final QC and Needle Detection: Before packaging, every toy goes through a final quality inspection for aesthetic flaws. Crucially, it then passes through a metal detector to ensure no broken needles or metal fragments are inside.

Key Points for Customizing Logos and Packaging?

Your logo and packaging can feel like a final, small detail. However, if they are not done well, they can make a high-quality product look cheap and unprofessional.

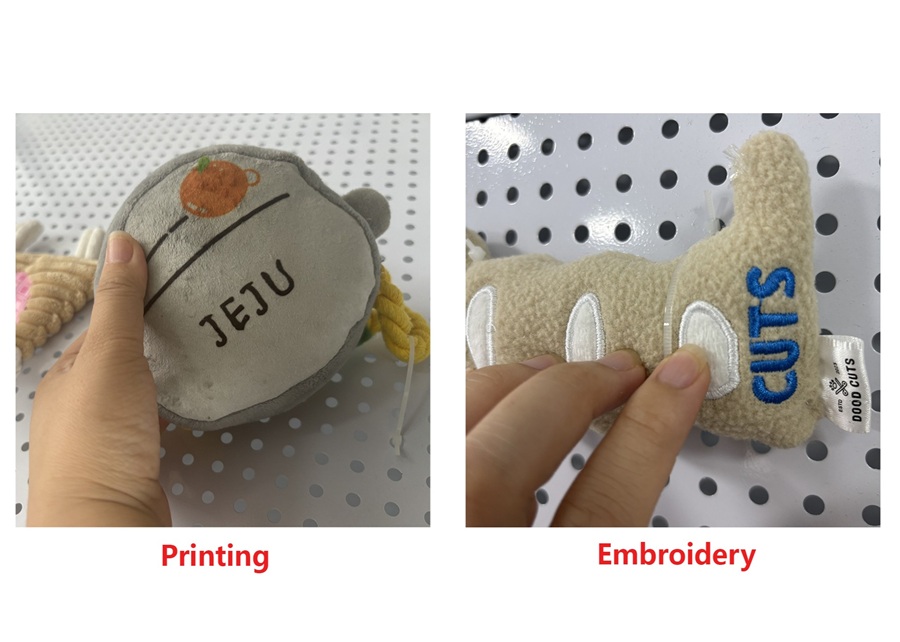

For your logo, choose embroidery for a premium, textured feel or printing for cost-effective promotions. For packaging, a well-designed hangtag or backer card is your silent salesperson, telling your brand story and grabbing attention on a crowded retail shelf.

Your branding is not an afterthought; it’s a critical part of the product experience. It’s the first thing a customer sees and a key driver of their purchase decision. We help you choose the right methods to ensure your branding elevates your product and maximizes its perceived value. It’s about making a smart choice that aligns with your brand identity and your budget.

Making the Right Branding Choices

Logo Application: The way your logo is applied to the toy speaks volumes about your brand.

| Method | Best For | Key Benefit |

|---|---|---|

| Embroidery | Premium brands seeking a high-end look. | Adds texture, durability, and a high-perceived value. |

| Woven Label | Brands with detailed logos or text. | Offers a clean, professional, and classic look. |

| Screen Printing | Promotional items or large graphic designs. | Cost-effective for large quantities and large-scale art. |

Packaging as a Sales Tool: Your packaging is your product’s first impression. A simple polybag is functional, but a custom backer card or hangtag can be a powerful marketing tool. It gives you space to tell your brand’s story, list product features, and show off your professional identity. It’s what separates a generic product from a thoughtful, branded experience.

How to Balance Cost and Quality in Plush Toys?

You need to hit a specific retail price point, but you’re worried about it. Cutting the wrong corners to save money can destroy your product’s quality and your brand’s reputation.

Balancing cost and quality is about making intelligent, targeted optimizations, not just cutting corners. We act as your partner, analyzing the cost of each component to find savings that don’t compromise the toy’s safety, durability, or appeal.

Many suppliers will just give you a final price. We believe in a more transparent, collaborative approach. We see ourselves as your cost optimization consultants. Our goal is to work with you to build the best possible product within your target budget. This means breaking down the costs and showing you exactly where your money is going. By looking at the cost structure together, we can often find significant savings in areas you might not have considered, all while protecting the core quality of your toy.

Smart Cost Optimization Strategies

We look at every element of the toy to find opportunities for smart savings.

- Material Adjustments: Sometimes, using a slightly different, yet equally safe and durable, fabric can result in significant savings. Or, we can adjust the density of the PP cotton filling—without impacting the toy’s feel—to reduce material costs.

- Construction Simplification: A complex seam might look nice, but a simpler, equally strong stitching technique could reduce labor time and cost. We can advise on where these changes make sense.

- Packaging and Logistics: Optimizing your packaging size and shape can dramatically reduce shipping costs. We work to minimize wasted space in every carton, which can save you a surprising amount on freight charges.

The key is that we make these decisions with you, explaining the trade-offs so you can make an informed choice that helps your bottom line without sacrificing quality.

Top 3 Hot Trends in the Plush Toy Market?

The pet product market moves fast. A design that was popular last year can look dated today, and you don’t want your brand to be left behind by new innovations.

The top trends are interactive puzzle toys that challenge a dog’s mind, sustainable toys made from recycled materials, and character-driven toys that appeal to the "pet parent." Tapping into these trends can give your brand a powerful edge in the market.

Staying ahead of the curve is essential for long-term success. We don’t just manufacture today’s orders; we keep our eye on the future to help our partners win tomorrow’s market. By understanding these key trends, you can develop products that are not only high-quality but also highly relevant and desirable to modern consumers. Each trend represents a clear business opportunity for your brand.

Trends and Opportunities

-

Trend: Interactive & Puzzle Toys

- What it is: These are toys with hidden pockets, flaps, or compartments where owners can hide treats. They turn playtime into a mentally stimulating challenge, helping to reduce boredom and anxiety.

- Business Opportunity: You can create a product line of puzzle toys with varying difficulty levels. This encourages customers to buy multiple products as their dog’s skills improve, leading to excellent repeat business.

-

Trend: Sustainable & Eco-Friendly Materials

- What it is: Consumers are increasingly concerned about their environmental impact. Toys made from materials like recycled polyester (from plastic bottles) or other sustainable fabrics are in high demand.

- Business Opportunity: This allows you to build a powerful brand story around sustainability. You can appeal directly to eco-conscious pet owners, a large and growing market segment that is willing to pay more for responsible products.

-

Trend: "Pet Parent" Appeal & Character Toys

- What it is: These are toys designed to amuse the owner as much as the pet. Think of plush toys shaped like a cup of coffee, a slice of avocado, or a video game controller.

- Business Opportunity: These products are highly shareable on social media. They are "Instagrammable" and tap into the owner’s personal identity and hobbies, creating a strong impulse to buy.

5 Criteria for Choosing a Plush Toy Manufacturer?

Choosing a manufacturing partner is the most important decision you’ll make. The wrong choice can lead to endless delays, quality issues, and lost revenue. It’s an overwhelming decision.

Focus on five key criteria: strong in-house design (ODM) capability, a transparent quality control system, deep expertise in global safety standards, flexible branding options, and a proven track record of clear communication and reliable logistics. These are non-negotiable.

To simplify your decision, we’ve created a definitive checklist. This isn’t just a list of our services; it’s the professional standard we believe every brand should demand from their manufacturing partner. When you evaluate potential suppliers, use these five points as your guide. A true partner should be able to confidently say "yes" to every single one.

The Essential Manufacturer Checklist

-

Do they offer true ODM and design partnership?

- Many factories can only copy a design (OEM). A true partner can take your rough idea and, like we did with Garrett’s pickleball paddle, help you co-create a unique, marketable product from scratch.

-

Is their quality control system transparent and verifiable?

- They shouldn’t just say they have QC. They should be able to walk you through their process, from raw material inspection to pre-shipment checks, and provide documentation.

-

Are they experts in global safety compliance?

- Your partner must understand the specific requirements for your target markets (e.g., ASTM F963 in the USA, EN71 in Europe) and have a history of producing compliant products.

-

Can they provide comprehensive branding and packaging solutions?

- A great partner offers more than just the toy. They should advise you on the best logo applications and help you design packaging that makes your product stand out and sells itself.

-

Do they guarantee clear communication and reliable logistics?

- You should have a dedicated, responsive point of contact. They should also actively help you optimize shipping and logistics to save you time and money.

If you are looking for a partner who meets all these criteria, we are ready to talk.

Conclusion

From concept to customer, creating a successful plush toy requires a partner who deeply understands safety, quality, and your unique brand vision. We are that partner, ready to help you succeed.

-

Exploring brand extension strategies can help you leverage your existing brand for new product opportunities. ↩